Cart

TPS-410 TPS-420 configure

TK-303 configure

ESE configure

ViscoScope® VA-100 configure

AD-310 configure

HD-100 | HD-102 | HD-104 configure

NP-256 configure

TRM-100 configure

ER-214 configure

NP-25X configure

NP-255 configure

NSP-X-E configure

QFS-3X configure

KST-20 Vento configure

LU-180 EX configure

QFS-2X configure

TK-302 configure

ZT-S configure

TK-304 configure

ES-21 configure

EE-24 configure

ZT-V configure

EFV2 20…230V configure

TK-308 configure

EP configure

KS-CAN-03 configure

PVS-390 configure

XR-4x2 configure

BK-380 configure

MO configure

T-200.L configure

XR-6x0 | XR-6x1 configure

ELH 230 V configure

Fluidix Lub-VDT configure

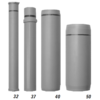

PPS-390 configure

ELH 24 V configure

ZMF-200e-IR configure

TPS-Serie

Sensors for determining the dew point in a wide range of applications

The dew point sensors of the enable direct measurement of the dew point and ambient temperature indoors and outdoors.

Operating conditions

- Temperature: : -40...80°C

- rel. Humidity : 0 - 100% rH

Measuring range

- measuring range (dew point) : -50...+80°C

- measuring range (Temperature) : -40...+80°C

- Measuring accuracy (temperature) : ± 0,2°C

- Signal output : 0...10V oder 4...20mA

ER-107

Electrode Relays with general approval for constructions Z-65.13-405, Z-65.40-191

Electrode relays for conductive level detection with approved design as part of an overfill cut-out device (Z-65.13-405) / leakage protection (Z-65.40-191)

Properties

- details : folgen

TPS-410 TPS-420

Compact, analogue dew point sensor

The dew point sensors of the enable direct measurement of the dew point and ambient temperature indoors and outdoors.

Properties TPS-410

- Operating voltage : 12...30V DC

- Power consumption : < 15mA

- Protection class Housing : IP66

- Protection class plug : IP67

- Weight : 96g

Properties TPS-420

- Operating voltage : 24V DC

- Loop voltage min: : Bürde(Ohm) *0,02 + 8 V

- Loop voltage max: : 30V

General properties

- Housing : Aluminium, eloxiert

- Dimensions (in mm) : 135 x Ø 19,2

Measuring range

- measuring range (dew point) : -50…+80 °C

- Measuring accuracy (humidity) : ± 2%

- measuring range (Temperature) : -40...+80°C

- Measuring accuracy (temperature) : ± 0,2°C

- Signal output : 0...10V | 4...20mA

ZDT-H

Differential pressure transmitter for high pressure applications

Versatile and reliable differential pressure transmitter for measuring air, non-aggressive media as well as liquids and oils.

Properties

- Pressure type : Differenzdruck

- Housing : Kunststoff mit LCD-Anzeige (oponal)

- Overpressure : 1,2* (1,5*) x Nenndruck

Measurement parameters

- Total error : ± 2,5 % FS (typ. ± 0,5 %)

- Linearity error : ± 1 % FS

- Signal output selection : 0...10 V 4...20 mA, 2-Leiter 4...20 mA, 3-Leiter

- Pressure range : 5…1.000 bar

Operating conditions

- Operating voltage : 14...28 VDC ± 10 %

- Operating temperature : 0...+50 °C

- Storage temperature : -20°C...+120°C

Connections

- Electrical connection : Schraubklemme im Gehäuse

- Process connection : G1/4" (andere auf Anfrage)

Lub-VDT USB-Kit

Software and USB kit for configuration & evaluation

Properties

- details : folgen

TK-303

Level transmitter for Ex-Zone 0 (Cat.1)

T30... continuous magnetic immersible probes are used for quasi-acquisition of the filling level in containers with liquid media.

Technical Data

- connection : Dose

- Protection class : IP 65

- Float type : 03, 04, 09

- Sliding tube length : max. 6000 mm

- Operating temperature : max. 135 °C

- Operating pressure : max. 20 bar (Kugel) max. 15 bar (Zylinder)

- Resolution : 7,5 mm | 10 mm

- Accessories : R/I-Wandler TK-101

MaterialDensity

- Type 03 : 0,75 g/cm³

- Type 04 : 0,65 g/cm³

- Type 09 : 0,76 g/cm³

ESE

Switching channel extension for ES series

TÜV-certified, type-tested electronic safety switching device (SIL2)

Properties

- Operating voltage : 16...32 V DC (max. 5,9 W)

- Dimensions : 150 x 60 x 42 mm (L x B x H)

- Housing : Aluminium (eloxiert)

- Protection class : IP65

Approvals

- DGRL 2014/68/EU Kat:IV : Baumustergeprüft gemäß Druckgeräterichtlinie

- DIN EN12263:1998 : Kälteanlagen und Wärmepumpen Sicherheitsschalteinrichtungen zur Druckbegrenzung -Anforderungen und Prüfungen; Kategorie IV

- DIN EN378:2020 : Kälteanlagen und Wärmepumpen - Sicherheitstechnische und umweltrelevante Anforderungen

- DIN EN61508:2011 : SIL2

Measuring ranges

- Measuring range relative pressure (nominal pressure) : -1…500 bar

- Measuring range differential pressure (nominal pressure) : 0…1 mbar - 0…1.000 mbar

- Setting accuracy (from nominal pressure) : 0,1 %

Operating conditions

- Pressure type : Relativdruck, Differenzdruck

- Temperature of the fluid : -40…+125 °C

- Ambient temperature : -20…+65 °C

- Parts in contact with media : Edelstahl

process connection

- Version relative pressure : G ¼“ Innengewinde

- Version differential pressure : G ⅛“ Innengewinde

- Adapter for process connection : 6mm; 8mm oder 10mm

electrical connection

- Analogue current output : 1x 4…20 mA

- Digital inputs/outputs : 2x Alarm oder 1x Alarm & 1x Fernentriegelung

Load capacity of the switching contacts DC (24V)

- DC1 : 16 A

- DC13 : 1,5A

Load capacity of the switching contacts AC (230V)

- AC1 : 16 A

- AC3 : 10 A

- AC15 : 7 A

ViscoScope® VA-100

Inline Viscometer

Maintenance-free inline viscosity sensor for precise and reliable real-time measurement of viscosity directly in the process.

Properties

- Material : 1.4571 / 1.4404 (316Ti / 316L)

- Protection class : IP65

- Process temperature : -10°C … +130°C | (integriertes Pt100 im Messfühler)

- max. process pressure : Vakuum ... 64 bar

- Process connections : NPT | M48 | Varivent® | Tri-Clamp

- Cable length sensor - transmitter : Max. 1.000 Meter

- max. flow velocity : 5 m / sec

- Ex approval : II 1/2G Ex ia IIC T6...T3 Ga/Gb | (optional)

Sensor types

- Sphere : VA-100B

- Cylinder : VA-100C

Repeatability

- VA-100B : ± 0,5% | ± 1 Digit

- VA-100C : ± 0,3% | ±1 Digit

Measuring ranges

- VA-100C : 0,1 - 2.500 mPa·s x g/cm³

- VA-100B : 10 - 25.000 mPa·s x g/cm³

Probe dimensions

- VA-100C : Ø 32 x 145 mm

- VA-100B : Ø 32 x 120 mm

installation positions

- Reservoir :

- tanks :

- Pipe :

- flow cell :

- Installation is position-independent :

AD-310

programmable Digital Display

The programmable digital display AD-31… can be used in all applications through the parameterization capability of the input values and the display area.

Properties

- Protection class EN60529 clamp : IP 20

- Protection class EN60529 front panel : IP 65

- Operating temperature : – 20...+ 60 °C

- nominal voltage : Weitbereichsnetzteil; 20 V DC ... 230 V AC

- Power consumption : max. ca. 3 VA

- Output contact : 2 Schließer / NO

- Switching voltage : max. 250 V AC, 300 V DC

- Switching current : max. 3 A , DC min. 30 mA

- Switching capacity : max. 50W, 100 VA

- Unregulated auxiliary voltage source : 15...20 V DC / 20 mA

- Display : LED 14 mm, 5-stellig

- Dimensions : 96x48x100 mm

- Weight : ca. 200 g

- Panel cut-out : H:45+0,6mm, B:92+0,8 mm

Equipment

- Measuring input current : 0(4)...20 mA DC

- Measuring input voltage : 0(2)...10 V DC

- Measuring input Potentiometric voltage divider : 1...100 kΩ

- Display : LED 14 mm, 5-stellig

- operation : Folientasten

- Display range : -19999...32000

- data backup : EEPROM

- measurement uncertainty : ±1 % oder ±1 Digit

- analogue output : 0 (4)...20 mA

KS-410 KS-420

Sensors for temperature & humidity measurement in aluminium or polycarbonate housing

The KS series sensors are modular temperature and humidity measurement sensors in compact housings for use in almost any application.

Specifications

- Housing shapes : Stabform | Alu- oder Polycarbonatgehäuse

- measurands : Temperatur | relative Feuchte

- Measuring range : -40...+80 °C | 0...100% rH

- Signal output : 0...10 V oder 4…20 mA

- Power supply : 12...30 V DC | 24 V DC

properties KG-410

- Operating voltage : 12...30V DC

- Power consumption : < 15mA

properties KG-420

- Operating voltage : 24V DC

- Loop voltage min: : Bürde(Ohm) *0,02 + 8 V

- Loop voltage max: : 30V

General properties

- Housing : Alu-Gehäuse mit Edelstahlstab oder Polycarbonat

- Dimensions (LxBxH in mm) : 30 x 45,4 x 97,3

- Protection type/class : Gehäuse IP66, Stecker IP 67

- Weight : 96g

Measuring range

- measuring range (Humidity) : 0…10% rH

- Measuring accuracy (humidity) : ± 2%

- measuring range (Temperature) : -40...+80°C

- Measuring accuracy (temperature) : ± 0,2°C

- Signal output : 0...10V | 4...20mA

HD-100 | HD-102 | HD-104

Hydrostatic immersion probes (0.8...10mWS)

Continuous and precise level measurement in unpressurised, open basins and tanks as well as underground applications such as shafts, wells and boreholes.

Properties

- Protection class EN60529 : IP68

- Operating temperature : -10...70 °C (PVC: -10...60 °C)

- Storage temperature : -25...70 °C (PVC: -10...60 °C)

- Power supply : 15...30 V DC

- power : max. 25 mA

- Output : 2-Leiter-Technik

- Measuring range : 0,8...10 mWs (Standard)

- Overpressure : abhängig vom Messbereich

- Deviation from characteristic curve : Nichtlinearität,

- Insulation resistance : > 100 kΩ

- Short-circuit resistance : permanent

- Reverse polarity protection : keine Schädigung o. Funktion bei vertauschten Anschlüssen

Materials

- Housing : Edelstahl 1.4571, PVC, PVDF

- Measuring cell : Edelstahl 1.4404, Keramik Al2o3 96%, Keramik Al2o3 99,9%

- Seals : FKM (Viton ®), EPDM, FFKM (Kalrez ®)

- Cable : PVC, PUR, FEP (Ø8 mm; 2 x 0,25 mm2 mit Luftschlauch und PTFE-Filter

NP-256

Level Switch - multiple 2...4 - pneumatic (hose)

very reliable and simple

sensors for scanning liquids, in

particular when used for overflow

protection. liquids can be

aggressive, sticky or highly contaminated

Properties

- Protection class EN60529 : IP 54

- connection thread : ab G2”

- Union nut : ab G2¾”

- Container connection flange : ab DN 25

- HoseØ : 13x2 mm

- Operating temperature : +60 °C

- medium temperatur : max. +60 °C

- Contact : Wechsler

- Switching capacity : 500 VA

- Switch-on point (Viton membrane) : 150 mm WS ±30 mm

- Switch-off point (MembraneViton) : 90 mm WS ±30 mm

Material

- Hose : PVC

- Screw fitting/grommet : PVC

- flange : PVC

- Connection head : PVC

Switching voltage

- silver : max. 250 V AC

- Gold : max. 24 V AC

Switching current

- silver : max. 6 A

- Gold : max. 100 mA

FluidIX Lub-6

Inline-capable oil condition sensor based on a multi-channel infrared measuring cell for permanent monitoring of the oil condition and prevention of machine damage

Based on non-dispersive infrared technology (NDIR), ZILA GmbH has developed an inline-capable measuring system that permanently monitors the oil condition directly in the system. The optical measuring system consists of a multi-channel infrared measuring cell with associated electronics and peripherals.

General information

- Housing : Robustes Aluminiumgehäuse

- Operating voltage : 18...36V DC (max. 400 mA @18V)

- Dimensions : 150 x 119 x 82 mm (L x B x H)

Operating conditions

- Operating temperature: : 0...+70 °C (optional 0...+90 °C)

- Maximum operating pressure: : 10 bar (optional 30 bar)

- Storage temperature: : -40...+90 °C

Connection

- ModBus TCP/IP : Ethernet-Port für Kommunikation über herstellerunabhängiges Busprotokoll

- Digital I/O ports : 1x Digital In 18...36V (10 mA max.), 4x Digital Out 18...36V (5 mA max.)

Operation

- User Interface : grafisch über Weboberfläche im eingebundenen Netzwerk

TRM-100

Turbidimeter (0...1.000 FNU or 500...4.000 FAU)

The turbidimeter TRM-100 is a compact device for measuring turbidity in liquids. The "turbidity" is measured using the scattered light method (angle 90 degrees) for the turbidity range of < 1,000 FNU (Formazine Nephelometric Units) and the transmitted light method (angle 0 degrees) for the turbidity ranges > 1,000 FAU (Formazine Attenuation Units).

Properties

- Operating pressure : max. 10 bar @ 20 °C | max. 2,5 bar @ 60 °C

- Measuring range : 500...4.000 FNU / FAU

- Measuring accuracy : +/-5 %

- Mounting position : horizontal

- Process connection : DN 20 | DN 40

- Flange connection : >= DN 20

- number of senders : 2

- number of receivers : 1

Material

- Seal : EPDM | optional FPM (Viton)

- Process connection : PVC | PPH

- Measuring tube : Borsilikatglas mit Nano Beschichtung

Input

- Power supply : 18...30 V DC

- Power consumption : < 2 W

Output

- Output contact : 4...20 mA

- Switching delay (adjustable) : 1...10 s

- Protection class : IP 65

- Switching voltage : max. 250 V AC | max. 115 V DC

- Switching current : max. 3 A

- Switching capacity : max. 500 VA, 60 Watt

- Potential-free changeover contact : 1 @ 1...10 s

T204-0.F

Immersible Magnetic Probe for Ex Zone 0 (Cat. 1)

The T20... magnetic immersion probes are used to detect fill level limits in containers for liquid media, where an explosive atmosphere of Zone 0 (Cat. 1) exists in the gas space above the liquid and an Ex-Zone 1 (Cat. 2) exists outside the container in the area of the junction box.

Properties

- connection : Kabel PUR blau

- Protection class : IP 68 Dose

- number of floats : max. 4x

- Operating temperature : max. 135 °C

- F-Contact : 1 / 12 kΩ

- Number of additional contacts : max. 3x Wechsler | 5x Schließer | 3x Öffner

- Switching current : 1 A, 2 A (nur mit Schirmung)

- Switching voltage : 230 V AC

Float

- Stainless steel ball 61 mm Ø : max. 20 bar | 0,65 g/cm³

- min. contact gap type 04 : 85 mm

Switching contacts and switching capacity

- Changeover contact : max. 3x | 60W/VA

- normally open : max. 5x | 100 W / VA

- Normally closed contact : max. 3x | 60 W/VA

T205-0.F

Ex area zone 0 (category 1)

The magnetic immersion probes T20... are used to detect fill level limit values in containers for liquid media, where an explosive atmosphere of zone 0 (cat. 1) is present in the gas space above the liquid and Ex zone 1 (cat. 2) is present outside the container, in the area of the junction box.

Properties

- Protection class EN60529 cable : IP 68

- connection cable : max. 10 Meter PUR

- Sliding tube length : Max. 6000 mm

- Operating temperature : max. 120 °C

- F-Contact : 1 / 12 kΩ

Float

- Stainless steel ball 44 mm Ø : max. 15 bar | 0,60 g/cm³

- Stainless steel cylinder 27 mm Ø : max. 10 bar | 0,78 g/cm³

Smart Pressostat App

App for control of ES-2X devices over Bluetooth

Android app for Bluetooth communication between smartphone or tablet and electronic safety switching devices from Fluid.iO

Properties

- platform : Android

- Android Version : 12

ELH

Suspension electrode as leakage probe

The leakage probes of the type series ELH are approved by the "DIBt" for the monitoring of collecting chambers, collecting devices, inspection and filling shafts.

General data

- Protection class : IP 68

- Probe body material : PE, PVC, PPH, PVDF

- Diameter probe body : 15 mm, 25 mm, 40 mm

- Operating temperature : atmosphärisch

- Operating pressure : atmosphärisch

- Resistance value of line monitoring : 22 kΩ / 100 kΩ

Material

- Screw connection : PVDF

- Cable : TPK ( PVC Basis)

- on request : FEP (Teflon), PVC - blau

- cable length : auf Wunsch (Standard 3 m)

- Material Sensor rods : Edelstahl (1.4571), Hastelloy B, Hastelloy C, Titan, Tantal, Glas-Kohlestifte

ER-214

Electrode Relays

Electrode relays for conductive level detection for all areas in which conductive, liquid media are to be detected, controlled or monitored

Properties

- Protection class EN60529 clamp : IP 20

- Protection class EN60529 front panel housing : IP 40

- Operating temperature : –20...+60 °C

- Storage temperature : –30...+80 °C

- AC nominal frequency : 48...62 Hz

- Power consumption : max. 1 W / VA

- Weight : ca. 150 g

Input

- Open circuit voltage : ≤ 10 V AC

- Short-circuit current : ≤ 5 mA

Output

- Contacts : 1 potentialfreie Wechselkontakte pro Kanal

- Switching voltage : min. 5 V | max. 250 V AC | max. 150 V DC

- Switching current : min. 5 mA | max. cosφ=1 3A | max. cosφ=0,7 1 A/AC | max. cosφ=1

- Switching capacity : min. 300 mW | max. 750 VA / 150 W (30 V DC / 5 A) / 18 W (150 V DC / 0,12 A)

- Working / Idle current : umschaltbar

- overvoltage category : EN 61010-1 Kategorie III

NP-25X

Pneumatic level switch

Reliable & simple probe for sensing aggressive, sticky or heavily contaminated liquids, especially suitable as overflow protection.

Properties NP-250 | NP-252

- Connection head : PA

- Protection class EN60529 Connection head : IP 54

- connection thread : ab G½”

- Container connection flange : ab DN 25

- Pitot tube material : PVC

- Material Screw connection : PVC

- Material flange : PVC

- Hose Ø : 16 mm / 25 mm

- Operating temperature : max. +60 °C

- medium temperatur : max. +60 °C

- Contact : Wechsler

- Switching voltage silver : 250 V AC

- Switching voltage gold : 24 V AC

- Switching current silver : 6 A

- Switching current gold : 100 mA

Properties NP-251 | NP-253

- Connection head : PS

- Protection class EN60529 Connection head : IP 54

- connection thread : ab G½”

- Container connection flange : ab DN 25

- Pitot tube material : 1.4571

- Material Screw connection : 1.4571

- Material flange : 1.4571

- Hose Ø : 15 mm / 28 mm

- Operating temperature : max. +60 °C

- medium temperatur : max. +90 °C

- Contact : Wechsler

- Switching voltage silver : 250 VAC

- Switching voltage gold : 24 V AC

- Switching current silver : 6 A

- Switching current gold : 100 mA

T200

Immersible Magnetic Probe made of PVC, PE, PPH, PTFE or stainless steel (1.4571)

Magnetic immersion probes for use with highly aggressive liquid media for detecting level limits in containers

Properties

- connection : Polyesterdose | Aluminiumdose

- Protection class EN60529 : IP 65 Anschlussdose

- Connector plug : 3- und 6-fach

- connection thread : G 1/8" | G 3/8" | G 1/4" | G 1/2" | G 1" | G1 1/4" | G1 1/2" | G2" | G3"

- connection cable : LiYY max. 80 °C | PTFE-Litze, 0,24 mm² | Silikon max. 150 °C

- Sliding tube length : max. 1000 mm (Rohr Ø 8 mm) | 6000 mm

- Operating pressure : max. 20 bar

- Viscosity : < 100 cp

- Protection class EN60529 : IP 68 Führungsrohr

- Switching voltage : max. 250 V

- Switching hysteresis : ca. 2...5 mm

- Holding range : ca. 12 mm

- Contact function : monostabil | bistabil

Operating temperature

- ltdata. : max. +60...+150 °C

- ltdata. : min. –20... –10 °C

- ltdata. : höhere oder niedrigere Temperaturen auf Anfrage

Switching capacity

- Changeover contact : 60 W/VA

- normally open : 100 W/VA

- Normally closed contact : 60 W/VA

Switching current

- Changeover contact : max. 1 A

- NO/NC contact : max. 2 A

Contacts

- Changeover contact : 8

- normally open : 10

- Normally closed contact : 7

T204-0

Magnetic immersion probe made of stainless steel (1.4571) as a cable tail variant

For use with highly aggressive liquid media to detect level limit values in containers. Suitable for use in hazardous areas, zone 0 (category 1).

Properties

- connection : Polyesterdose | Aluminiumdose

- Protection class EN60529 : IP 65 Anschlussdose

- Connector plug : 3- und 6-fach

- connection thread : G 1/8" | G 3/8" | G 1/4" | G 1/2" | G 1" | G1 1/4" | G1 1/2" | G2" | G3"

- connection cable : LiYY max. 80 °C | PTFE-Litze, 0,24 mm² | Silikon max. 150 °C

- Sliding tube length : max. 1000 mm (Rohr Ø 8 mm) | 6000 mm

- Operating pressure : max. 20 bar

- Viscosity : < 100 cp

- Protection class EN60529 : IP 68 Führungsrohr

- Switching voltage : max. 250 V

- Switching hysteresis : ca. 2...5 mm

- Holding range : ca. 12 mm

- Contact function : monostabil | bistabil

Operating temperature

- ltdata. : max. +60...+150 °C

- ltdata. : min. –20... –10 °C

- ltdata. : höhere oder niedrigere Temperaturen auf Anfrage

Switching capacity

- Changeover contact : 60 W/VA

- normally open : 100 W/VA

- Normally closed contact : 60 W/VA

Switching current

- Changeover contact : max. 1 A

- NO/NC contact : max. 2 A

Contacts

- Changeover contact : 8

- normally open : 10

- Normally closed contact : 7

NP-255

Level Switch - multiple 2...4 - pneumatic

very reliable and simple

sensors for scanning liquids, in

particular when used for overflow

protection. liquids can be

aggressive, sticky or highly contaminated

Properties

- Protection class EN60529 : IP 54

- connection thread : ab G2”

- Union nut : ab G2¾”

- Container connection flange : ab DN 25

- Hose Ø : 16 mm

- Operating temperature : +60 °C

- medium temperatur : max. +60 °C

- Contact : Wechsler

- Switching capacity : 500 VA

- Switch-on point (Viton membrane) : 150 mm WS ±30 mm

- Switch-off point (MembraneViton) : 90 mm WS ±30 mm

Material

- Pitot tube / Hose : PVC

- Screw fitting/grommet : PVC

- flange : PVC

- Connection head : PVC

Switching voltage

- silver : max. 250 V AC

- Gold : max. 24 V AC

Switching current

- silver : max. 6 A

- Gold : max. 100 mA

T-200.L

Leakage probes with general building authority approval

The leakage probes T-200.L are approved by the "DIBt" on the basis of the "WasBauPVO" for the detection of leaked liquids hazardous to water.

DSM2420

Sensor for simultaneous measuring flow velocity and filling level

The DSM2420 sensor is a combined sensor for simultaneous measuring flow velocity and level in open or accessible closed channels of all types and shapes.

Properties

- Dimensions : 180 x 48 x 36,5 mm ( L x B x H )

- Weight : ca. 1,5 kg

- Protection class : IP68

- Cable length (standard) : 15 m

- Bending radius : > 10 x D (Kabeldurchmesser 6,25mm) = > 62,5mm

- Temperature range : 0°C ... 50°C

- Mounting shoe material : V2A 1,5mm

Certificates

- EX / ATEX : IBExU 04 ATEX 1256

Measuring principle

- Flow velocity: Ultrasonic Doppler :

- Filling level: Differential pressure :

Flow velocity

- Measuring range : 0,01 - 4 m / s

- Measuring accuracy : +/- 5 % vom Momentanwert im Kanal

- Temperature drift : 0,1% / °C ( Meßspanne )

- Temperature drift : 0,05% / °C ( Nullpunkt )

- Output signal : 4 - 20 mA

Filling level

- Measuring ranges : 0 –1 m ; 0 – 2 m ; 0 – 4 m

- Measuring accuracy : < 0,2% v.E. Summe aus Nichtlinearität, Hysterese und Wiederholbarkeit

- Temperature drift : 0,005% / °C v.E. Meßspanne

- Temperature drift : 0,005% / °C v.E. Nullpunkt

- Material : Al2O3 (96%) aktive Fläche

- Output signal : 4 – 20 mA

- Zero point : norm 4 mA ( +/- 3 % )

KST-20 Vento-RN

Climate control with aH-Controlled technology and Rn-Protected seal

The KST-20 Vento/RN is a climate control unit with aH-Controlled technology and Rn-Protected seal for ventilation and dehumidification of all types of private, commercial and industrial rooms. With the three operating modes for ventilation, dehumidification and radon measurement, the KST-20 Vento climate control unit can be used flexibly in almost all living, working and industrial areas.

Properties

- Power supply : 230 V AC

- Protection class : IP 65

- Dimensions (LxBxH) : 160 x 90 x 50 mm

- Housing : hochwertigem ASA+PC (UL 94 V-0) für harte Beanspruchung, flammwidrig und selbstverlöschend

- Signal output : I²C

Measuring range

- measuring range (Humidity) : 0…100 % rF

- Measuring accuracy (humidity) : ±2 %

- measuring range (Temperature) : -40…+80 °C

- Measuring accuracy (temperature) : ±0,2 °C

- measuring range (radon) : 0...1200 Bq/m³

- Adjustable limits : 80...1000 Bq/m³

NSP-X-E

Vibrating Limit Switch

The vibrating limit switch is a level limit switch for all kinds of fluids and is used in tanks, containers and pipelines.

Properties

- Protection class EN60529 : IP 65/IP 67

- Operating pressure : ≤ 40 bar

- media density : ρ ≥ 0,7 g/cm³

- Viscosity : max. 10000 mm²s

- Rated current : < 15 mA

- Protection class : III

- Output : PNP

- power : kurzschlussfest, überlastsicher

- Display : LED (grün, rot)

- Switching delay (cover) : ca. 0,5 s

- Switching delay (release) : ca. 1 s

NSP-1-E

- connection thread : G 1”

- Operating temperature : –40...+150 °C

- Storage temperature : –40...+85 °C

- nominal voltage : 10...55 V DC (verpolsicher)

- Current output : ≤ 350 mA

NSP-2-E

- connection thread : G ½”

- Operating temperature : –40...+100 °C

- Storage temperature : –20...+70 °C

- nominal voltage : 10...35 V DC (verpolsicher)

- Current output : ≤ 250 mA

QFS-3X

Mercury-free float switch with µ-switch

Properties

- Protection class EN60529 : IP 68

- Cable entry : PVC , PTFE bzw. PVDF

- Conductor cross-section : 3 x 0,75 mm², PUR 3x 0,5mm²

- Operating pressure cylinder : max. 1 bar

- Operating pressure sphere : max. 2 bar

- Switching system : µ-Schalter

- Contact : Wechsler, NO, NC

Material Float

- QFS-30 : PPH (Polypropylen)

- QFS-31 : PPH (Polypropylen)

- QFS-34 : PE (Polyethylen)

Cable

- TPK : PVC Basis Ø 5,9 mm

- TPKV : PVC verstärkt Ø 7,3 mm

- PUR : Polyurethan Ø 5,4 mm

- SIL : Silikon Ø 6,4 mm

- FEP : Teflon Ø 4,0 mm

- AEM : Ethylen-Acrylat-Kautschuk

Cable length between float & attachment

- TPK : 70 mm

- TPKV : 90mm

- PUR : 100mm

- SIL : 80 mm

- FEP : 110 mm

- AEM : abhängig vom Innenkabel

Operating temperature

- TPK(V), AEM : max. + 60 °C

- PUR : max. + 70 °C

- Silicone,Tefloncable with PE float : max. + 80 °C

- Silicone, Teflon cable with PP float : max. + 85 °C

MaterialDensity

- QFS-31 : ≥≥ 0,6 g/cm³

- QFS-34 : ≥≥ 0,75 g/cm³

- QFS-30 TPK(V) cable : ≥≥ 0,85 g/vcm³

- QFS-30 PUR cable : ≥≥ 0,95 g/cm³

- QFS-30 SIL cable : ≥≥ 0,90 g/cm³

- QFS-30 FEP cable : ≥≥ 0,95 g/cm³

- QFS-30AEM cable : ≥≥ 0,90 g/cm³

KST-20 Vento

Automatic, controlled ventilation and dehumidification as well as cooling of rooms with aH-Controlled technology*.

The KST-20 Vento is a climate control unit with aH-Controlled technology for ventilation, dehumidification and cooling for all types of private, commercial and industrial rooms. With the three operating modes for ventilation, dehumidification and cooling, the KST-20 Vento climate control can be used flexibly in almost all living, working and industrial areas.

Properties

- Power supply : 230 V AC

- Protection class : IP 65

- Dimensions (LxBxH) : 160 x 90 x 50 mm

- Housing : hochwertiges ASA+PC (UL 94 V-0) für harte Beanspruchung, flammwidrig und selbstverlöschend

- Signal output : I²C

Measuring range

- measuring range (Humidity) : 0…100% rF,

- Measuring accuracy (humidity) : ±2%

- measuring range (Temperature) : -40…+80°C

- Measuring accuracy (temperature) : ±0,2°C

LU-180 EX

Compact Ultrasonic Level Sensor

The LU-150 is a short-range integrated ultrasonic level transmitter, intrinsically safe as Ex-version LU-180. This general purpose, 2 wire, 4 to 20 mA loop powered transmitter is ideal for liquids, slurries, and bulk materials in open or closed vessels to 5 m (16.4 ft).

Properties

- Protection class EN60529 : IP 68

- Power supply : 12...30 V DC / 0.1A Spitze

- Power consumption : Max. 0,75 W (25 mA bei 24 V DC)

- Output : 4...20 mA

- Max. Load : 600 Ω bei 24 V DC

- Measuring span : Proportional oder umgekehrt proportional

- Measurable materials : Flüssigkeiten, Schlämme, Schuttgüter

- operating temperature : –20...+60 °C

- Opening angle : 12°

- working pressure : Atmosphärisch

- Display : 3-stelliges LCD

- Process connection : Gewinde G 2" (BSPP) EN 10226 PVDF

- Weight : 1,3 Kg

- Cable entry : Kabelverschraubung M 20 x 1.5

- Material housing electronics : Polybutylenterephthalat PBT

- Material sensor / thread : PVDF-Copolymer

Input

- Measuring range : 0,25...5,0 m

- frequency : 54 kHz

Measuring Accuracy

- Measurement deviation : ± 0,25 % vom Messbereich (in Luft)

- Resolution : 3 mm

- Temperature compensation : im Sensor integriert

- Echo processing : „Sonic Intelligence“ von Siemens

T209

Immersible Magnetic Probe made of PVC, PE, PPH, PTFE or stainless steel (1.4571)

Magnetic immersion probes for use with highly aggressive liquid media for detecting level limits in containers

Properties

- connection : Polyesterdose | Aluminiumdose

- Protection class EN60529 : IP 65 Anschlussdose

- Connector plug : 3- und 6-fach

- connection thread : G 1/8" | G 3/8" | G 1/4" | G 1/2" | G 1" | G1 1/4" | G1 1/2" | G2" | G3"

- connection cable : LiYY max. 80 °C | PTFE-Litze, 0,24 mm² | Silikon max. 150 °C

- Sliding tube length : max. 1000 mm (Rohr Ø 8 mm) | 6000 mm

- Operating pressure : max. 20 bar

- Viscosity : < 100 cp

- Protection class EN60529 : IP 68 Führungsrohr

- Switching voltage : max. 250 V

- Switching hysteresis : ca. 2...5 mm

- Holding range : ca. 12 mm

- Contact function : monostabil | bistabil

Operating temperature

- ltdata. : max. +60...+150 °C

- ltdata. : min. –20... –10 °C

- ltdata. : höhere oder niedrigere Temperaturen auf Anfrage

Switching capacity

- Changeover contact : 60 W/VA

- normally open : 100 W/VA

- Normally closed contact : 60 W/VA

Switching current

- Changeover contact : max. 1 A

- NO/NC contact : max. 2 A

Contacts

- Changeover contact : 8

- normally open : 10

- Normally closed contact : 7

XR Relais

Electrode relays and contact protection relays

The electrode relays are used for conductive level detection.

levels. The possible applications extend

areas where conductive, liquid media are to be detected, controlled

to be detected, controlled or regulated. Hereby

level detection (overflow / dry run) as well as minimum / maximum

as well as minimum / maximum controls can be realised.

The contact protection relays are universal measuring transducers, which

input signals (resistance values) with "Namur" specification (DIN EN 60947).

Namur" specification (DIN EN 60947) into switching signals of floating

output contacts.

Protection class EN60529

- clamp : IP20

- Housing : IP40

Technical Data

- Operating temperature : -20...+60 °C

- Storage temperature : -30...+80 °C

- Output contacts : potentialfrei

- Switching voltage : min. 5 V | max. 250 V AC / 150 V DC

- Switching current : min. 5 mA | max. 5 A AC / 5 A DC

- Switching capacity : min. 300 mW | max. 100 VA / 50 W

- Quiescent current : umschaltbar

- Weight : ca. 250 g

- CE marking : siehe Konformitätserklärung

- Ex-protection/IECEx : siehe Prüfbescheinigung

ER-104

1-channel electrode relay

Electrode relays for conductive level detection for all areas in which conductive, liquid media are to be detected, controlled or monitored

Properties

- Protection class EN60529 clamp : IP 20

- Protection class EN60529 front panel housing : IP 40

- Operating temperature : –20...+60 °C

- Storage temperature : –30...+80 °C

- Weight : ca. 150g

- ltdata. :

Power supply

- nominal voltage : siehe Typenschlüssel

- AC nominal frequency : 48...62 Hz

- Power consumption : max. 1 W / VA

Input

- Open circuit voltage : ≤ 10 V AC

- Short-circuit current : ≤ 5 mA

- Switching delay : siehe Typenschlüssel

- Sensitivity range : siehe Typenschlüssel

Output

- Contacts : potentialfreie Wechselkontakte

- Switching voltage(min) : 5 V

- Switching voltage (max) : 250 V AC / 150 V DC

- Overvoltage category : EN 61010-1 Kategorie III

Switching current

- Switching current : min. 5 mA

- Switching current : max. cos φ =1 5 A

- Switching current : max. cos φ = 0,7 3 A/AC

- Switching current : max. cos φ = 1

T200 Ex

Magnetic immersion probes with TÜV 02 ATEX 1795X approval for Ex zone 0

Magnetic immersion probes for detecting fill level limit values in containers for liquid media, where an explosive atmosphere of zone 0 (category 1) is present in the gas space above the liquid and zone 1 (category 2) outside the container in the area of the junction box

Properties

- connection : Polyesterdose | Aluminiumdose

- Protection class EN60529 : IP 65 Anschlussdose

- Connector plug : 3- und 6-fach

- connection thread : G 1/8" | G 3/8" | G 1/4" | G 1/2" | G 1" | G1 1/4" | G1 1/2" | G2" | G3"

- connection cable : LiYY max. 80 °C | PTFE-Litze, 0,24 mm² | Silikon max. 150 °C

- Sliding tube length : max. 1000 mm (Rohr Ø 8 mm) | 6000 mm

- Operating pressure : max. 20 bar

- Viscosity : < 100 cp

- Protection class EN60529 : IP 68 Führungsrohr

- Switching voltage : max. 250 V

- Switching hysteresis : ca. 2...5 mm

- Holding range : ca. 12 mm

- Contact function : monostabil | bistabil

Operating temperature

- ltdata. : max. +60...+150 °C

- ltdata. : min. –20... –10 °C

- ltdata. : höhere oder niedrigere Temperaturen auf Anfrage

Switching capacity

- Changeover contact : 60 W/VA

- normally open : 100 W/VA

- Normally closed contact : 60 W/VA

Switching current

- Changeover contact : max. 1 A

- NO/NC contact : max. 2 A

Contacts

- Changeover contact : 8

- normally open : 10

- Normally closed contact : 7

T201 PTFE

Immersible Magnetic Probe made of PTFE

Magnetic immersion probes for use with highly aggressive liquid media for detecting level limits in containers

Properties

- connection : Polyesterdose | Aluminiumdose

- Protection class EN60529 : IP 65 Anschlussdose

- Connector plug : 3- und 6-fach

- connection thread : G 1/8" | G 3/8" | G 1/4" | G 1/2" | G 1" | G1 1/4" | G1 1/2" | G2" | G3"

- connection cable : LiYY max. 80 °C | PTFE-Litze, 0,24 mm² | Silikon max. 150 °C

- Sliding tube length : max. 1000 mm (Rohr Ø 8 mm) | 6000 mm

- Operating pressure : max. 20 bar

- Viscosity : < 100 cp

- Protection class EN60529 : IP 68 Führungsrohr

- Switching voltage : max. 250 V

- Switching hysteresis : ca. 2...5 mm

- Holding range : ca. 12 mm

- Contact function : monostabil | bistabil

Operating temperature

- ltdata. : max. +60...+150 °C

- ltdata. : min. –20... –10 °C

- ltdata. : höhere oder niedrigere Temperaturen auf Anfrage

Switching capacity

- Changeover contact : 60 W/VA

- normally open : 100 W/VA

- Normally closed contact : 60 W/VA

Switching current

- Changeover contact : max. 1 A

- NO/NC contact : max. 2 A

Contacts

- Changeover contact : 8

- normally open : 10

- Normally closed contact : 7

QFS-2X

Stainless Steel Float Switch

QFS-20 & QFS-21 float switches have stainless steel floats and one or two reed contacts.

Properties

- Protection class EN60529 : IP68

- Material Float : VA 1.4571

- Material hose : Edelstahlwellschlauch (1.4404) mit Edelstahldrahtumflechtung (1.4301)

- Operating temperature : max. + 150 °C

- media density : ρ ≥ 0,8g/cm³

- Switching system : Reed-Schalter

- Contact : Wechsler, NO, NC

- Switching voltage : 4...250 V AC/DC

- Switching current : 1 mA ...1 A

- Switching capacity : max. 1A, 60 VA/60 W

- Switching hysteresis : ca. 100 mm

- Switching angle : ca. + 20° / – 20°

- Operating pressure (QFS-20) : max. 15 bar

- Operating pressure (QFS-21) : max. 6 bar

TK-302

Level transducer made of brass and stainless steel

T30... continuous magnetic immersible probes are used for quasi-acquisition of the filling level in containers with liquid media.

Technical Data

- connection : Dose

- Protection class socket / plug : IP 65

- Protection class EN60529 cable : IP 55

- Float type : 03 (04)

- connection cable : 1000 mm Silikon 0,5 mm²

- Sliding tube length : max. 6000 mm

- Operating temperature : max. 130 °C

- Operating pressure : max. 20 bar

- Resolution : 10 mm | 15 mm | 1 % | 2 % | 5 %

- Accessories : R/I-Wandler TK-101

MaterialDensity

- Type 03 : 0,75 g/cm³

- Type 04 : 0,65 g/cm³

ZT-S

Functionally safe pressure transmitter for ES series

Reliable pressure measurement and optimal process monitoring thanks to the ZT series. Developed for high demands and safety-critical applications

Properties

- Operating voltage : 12...32 V DC (max. 0,2 W)

- Dimensions : Ø 22 x 59 (D x H), SW22

- Housing : Edelstahl

- Measuring range nominal pressure : -1…500 bar

- Overpressure : 2 x Nenndruck

- Bursting pressure : 4 x Nenndruck

- Protection class : IP65

- Output signal : ZILA-DIO

Operating conditions

- Pressure type : Relativdruck

- Temperature of the fluid : -40 …+125 °C

- fluid temperature (optional) : -20 …+125 °C

- Ambient temperature : -40 …+105 °C

electrical connection

- Standard : Binder M12 x 1

TK-304

Level transmitter for Ex-Zone 0 (Cat.1)

T30... continuous magnetic immersible probes are used for quasi-acquisition of the filling level in containers with liquid media.

Technical Data

- connection : Dose

- Protection class Socket : IP 65

- Float type : 03, 04, 09

- Sliding tube length : max. 6000 mm

- Operating temperature : max. 135 °C

- Operating pressure : max. 20 bar (Kugel) max. 15 bar (Zylinder)

- Resolution : 7,5 mm | 10 mm

- Accessories : R/I-Wandler TK-101

MaterialDensity

- Type 03 : 0,75 g/cm³

- Type 04 : 0,65 g/cm³

- Type 09 : 0,76 g/cm³

ES-21

Electronic safety switching device with 1 safety function

TÜV-certified, type-tested electronic safety switching device (SIL2)

Properties

- Operating voltage : 16...32 V DC (max. 5,9 W)

- Dimensions : 150 x 60 x 42 mm (L x B x H)

- Housing : Aluminium (eloxiert)

- Protection class : IP65

Approvals

- DGRL 2014/68/EU Kat:IV : Baumustergeprüft gemäß Druckgeräterichtlinie

- DIN EN12263:1998 : Kälteanlagen und Wärmepumpen Sicherheitsschalteinrichtungen zur Druckbegrenzung -Anforderungen und Prüfungen; Kategorie IV

- DIN EN378:2020 : Kälteanlagen und Wärmepumpen - Sicherheitstechnische und umweltrelevante Anforderungen

- DIN EN61508:2011 : SIL2

Measuring ranges

- Measuring range relative pressure (nominal pressure) : -1…500 bar

- Measuring range differential pressure (nominal pressure) : 0…1 mbar - 0…1.000 mbar

- Setting accuracy (from nominal pressure) : 0,1 %

Operating conditions

- Pressure type : Relativdruck, Differenzdruck

- Temperature of the fluid : -40…+125 °C

- Ambient temperature : -20…+65 °C

- Parts in contact with media : Edelstahl

process connection

- Version relative pressure : G ¼“ Innengewinde

- Version differential pressure : G ⅛“ Innengewinde

- Adapter for process connection : 6mm; 8mm oder 10mm

electrical connection

- Analogue current output : 1x 4…20 mA

- Digital inputs/outputs : 2x Alarm oder 1x Alarm & 1x Fernentriegelung

Load capacity of the switching contacts DC (24V)

- DC1 : 16 A

- DC13 : 1,5A

Load capacity of the switching contacts AC (230V)

- AC1 : 16 A

- AC3 : 10 A

- AC15 : 7 A

EE-24

Ex-Electrode-single with integrated safety barrier

When using a threshold detection electrode with integrated safety barrier, exceeding or falling below a threshold in conductive fluids in Ex-Zone 0 (category 1) can be detected.

Properties

- connection thread : G 1/2” Standard | G 3/4” | G1”

- Cable : TPK (Standard) | SIL (Silikon) | FEP (Teflon)

- rod length : max. 6.000 mm

- Operating pressure : max. 40 bar

Material

- electrode body : Edelstahl 1.4571

- Process connection : Edelstahl 1.4571

- Coating : PTFE

- electrode rod : Edelstahl 1.4571

- on request : Hastelloy C | Tantal

ZT-V

Reliable pressure measurement and optimum process monitoring with the ZT series

From low to high pressure and suitable for liquid and gaseous media.

Connection

- Signal output : 0...10 V, 3-Leiter | 0,5...4,5, ratiometrisch | 4...20 mA, 2-Leiter

- Electrical connection : DIN EN 175301-803 A | DIN EN 175301-803 C | Binder M12x1 (Serie 713)

- Process connection : G 1/4" ISO 1179-2 (Male Form E) | 1/4" NPT | 7/16" 20 UNF Male

- measuring range (bar) : 0…0,6 | 0…600

Properties

- Pressure type : Relativdruck | Absolutdruck

- Housing : Edelstahl

- Overpressure : 1,5* fach bis 400 bar, darüber 1,2* fach

- Bursting pressure : 3* fach bis 600 bar, darüber 1,5* fach

Measurement parameters

- response time : < 1 ms

- Total error : ≤ 0,5 % FS

- Non-linearity : ≤ 0,2 % FS

- Non-repeatability : ≤ 0,10 % FS

- Hysteresis : ≤ 0,15 % FS

ambient conditions

- Temperature of the fluid : -40...+125 °C (0...+80 °C kompensierter Bereich)

- Ambient temperature : -40...+105 °C

- Storage temperature : -40°C...+125°C

- Shock resistance : g 1000 gemäß IEC 60068-2-32

- Vibration resistance : g 20 gemäß IEC 60068-2-6

EFV2 20…230V

Conductive electrodes with 24...230 V direct connection

The overfill protection EFV2 (24...230 V AC/DC) is approved by the "DIBt" as overfill protection for liquids hazardous to water.

Properties

- connection : Polyesterdose (PO)

- Protection class : IP 65

- connection thread : G2"

- Union nut : G2¾" | S 100x8

- Material Screw connection : PE, PVC, PPH, PVDF

- Material Sensor rods : Edelstahl (1.4571), Hastelloy B, Hastelloy C, Titan, Tantal, Kohlestifte

- Operating pressure : atmosphärisch

- Resistance value of line monitoring : 100 kΩ

- Adjustable sensitivity range : 2..100 kΩ

Operating temperature

- PE : atmosphärisch

- PVC : atmosphärisch

- PPH : 90 °C

- PVDF : 100 °C

Power supply

- nominal voltage : 24...230 V AC/DC

- Power consumption : ≤ 2 W

Output

- potential-free changeover contacts : 2

- Switching voltage : max. 250 V AC / 30 V DC

- Switching current : max. 5 A AC / 5 A DC

- Switching capacity : max. 750 VA / 90 W

- displays : Betriebs- LED grün Funktions-LED rot

- Switching delay : ca. 0,5 s

TK-308

Liquid Level Measuring Instruments Series

T30... continuous magnetic immersible probes are used for quasi-acquisition of the filling level in containers with liquid media.

Technical Data

- Protection class socket / plug : IP 65

- Protection class EN60529 cable : IP 55

- Float type : 11,12, 15, 17

- connection cable : 1000 mm LiYY 0,5 mm² oder Silikon 0,5 mm²

- Sliding tube length : max. 6000 mm

- Operating pressure : max. 6 bar

- Resolution : 7,5 mm | 10 mm | 15 mm | 20 mm | 1 % | 2 % | 5 %

- Accessories : R/I-Wandler TK-101

Operating temperature

- PVC : max. 60 °C

- PE : max. 80 °C

- PP : max. 90 °C

MaterialDensity

- Type 11 : 0,60 g/cm³

- Type 12 : 1,00 g/cm³

- Type 15 : 0,59 g/cm³

- Type 17 : 0,63 g/cm³

DS-CAN-01

CANopen pressure transmitter with CAN bus signal output

Versatile, media-compatible pressure transmitter with CAN bus interface.

technical properties

- Pressure type : Relativdruck gegen Umgebungsdruck bzw. gegen interne Atmosphäre

- measuring resolution : 10 Bit

- Measuring accuracy : Klasse 0,5 bei RT

- Total error : < 1,5 % v.E bei -10 °C … +80 °C.

- measuring grid : ab 5 ms

- CAN protocol : CANopen 2.0 A

- Physical Layer : nach DIN 11898

ambient conditions

- Operating temperature range : -40 °C … +80 °C

- Storage temperature range : -40 °C … +120 °C

- Shock resistance : 30 g, Dauer

- Vibration resistance : 10 g bei 20-1000 Hz

- EMC/ESD : EN 50082-1 und EN 50082-2

- Duration : 14 ms bei RT

Pressure measuring ranges

- kPa : bar

- 0...500 : 0…5

- 0...1.000 : 0…10

- 0...2.000 : 0…20

- 0...5.000 : 0…50

- 0...10.000 : 0…100

- 0...35.000 : 0…350

- 0...50.000 : 0…500

- 0...70.000 : 0…700

- 0...200.000 : 0…2.000

- 0...400.000 : 0…4.000

- Standard pressure range : in kPa

- Non-standard ranges : auf Anfrage erhältlich

EP

Plate Electrode as Leak Detector (conductive)

with general approval for constructions and EC-Type-Examination Certificate for Ex-zone 1(Cat. 2)

Properties

- Protection class EN60529 : IP 68

- Operating temperature : atmosphärisch

- Operating pressure : atmosphärisch

- Resistance value of line monitoring : 22 kΩ / 100 kΩ

- cable length : auf Wunsch

Material

- Cable : TPK (PVC Basis)

- Sensor rods : Edelstahl (1.4571) | Hastelloy B | Hastelloy C | Titan | Tantal | Glaskohlenstoff

Options

- cable material : FEP (Teflon) | EX (PVC blau)

KS-CAN-03

CANopen Climate Transmitter

Climate transmitter KS-CAN-03 for temperature and humidity measurement, according to CAN bus specifications with a digital climate probe

Properties

- Housing : Aluminium, eloxiert

- Measuring element humidity : kapazitiv, betauungsfest

- Measuring element temperature : Halbleiter

- measuring resolution : 12 Bit

- measuring grid : ab 5 ms

ElectricalConnection

- CAN protocol : CANopen 2.0 A, nach ciA DS 404

- Physical Layer : nach DIN 11898

- Option : Bereistellung des EDS-Files

tdata.

- Operating temperature : -40...+80 °C

- Storage temperature : -40°C...+120°C

- Minimum air velocity across the sensor required for measurement : 1,5 m/s

PVS-390

PVC float with magnet insert

for actuating monostable and bistable contacts

Variants

- 40 : AußenØ 40 x 165 mm, für RohraußenØ 50 mm Gewicht ca. 145 g

- 50 : AußenØ 50 x 125 mm, für RohraußenØ 63 mm Gewicht ca. 156 g

XR-4x2

Electrode relay with ATEX and WHG approval

The electrode relays are used for conductive level detection.

levels. The possible applications extend

areas where conductive, liquid media are to be detected, controlled

to be detected, controlled or regulated. Hereby

level detection (overflow / dry run) as well as minimum / maximum

as well as minimum / maximum controls can be realised.

Protection class EN60529

- clamp : IP20

- Housing : IP40

Technical Data

- Operating temperature : -20...+60 °C

- Storage temperature : -30...+80 °C

- Output contacts : potentialfrei

- Switching voltage : min. 5 V, max. 250 V AC / 150 V DC

- Switching current : min. 5 mA, max. 5 A AC / 5 A DC

- Switching capacity : min. 300 mW, max.100 VA / max. 50 W

- CE marking : siehe Konformitätserklärung

- Ex-protection/IECEx : siehe Baumusterprüfbescheinigung

- Weight : ca. 170 g

BK-380

Bistable change-over contact

Magnetically actuated changeover switch,

which permanently changes its electrical switching state as a result of a magnetic system passing by, depending on the direction of movement.

Properties

- Protection class EN60529 : IP 65

- Operating temperature : –25...+70 °C

- Wire cross-section max. : 1,5mm²

- Switching point distance between two contacts : min. 40 mm

- Switching hysteresis : ca. 10-15 mm

Material

- Housing : Polycarbonat

- Mounting clip : V2A, Kabelbinder (PP)

- Rivet : V2A

- Screw connection : M 20 x 1.5, Polyamid

Weight

- BK-390-50 : 137 g

- BK-390-63 / BK-380 : 140 g

Switching contact

- Switching voltage : 5...250 V AC/DC

- Switching current : 1mA...6 A AC/DC

- Switching capacity(min.) : 300 VA, 60 W

- Switching capacity(max.) : 5 mW

MO

Monostable Switch

Properties

- Protection class : IP 65

- Switching current : max. 1 A

- Switching voltage : max. 24 V

- Switching capacity : max. 20 W/VA

Material

- Housing : Messingrohr Ø 10 x 1

- Cable : TPK (PVC basis) | SIL (Silikon)

Operating temperature

- TKP : –15 ° ... + 60 °C

- SIL : –15 ° ... +130 °C

T-200.L

Leakage probes with general building authority approval

The leakage probes T-200.L are approved by the "DIBt" on the basis of the "WasBauPVO" for the detection of leaked liquids hazardous to water.

Connection

- Box : Polyesterdose (PO)

- Box : Polyethylen-Anschlusskopf (PE)

- Cable : Kabel (TPK)

- Plug : Stecker (ST)

Properties

- Protection class : IP 65

- Cable entry : PVDF-Verschraubung , PVC-Dichtung

- Material Float : PE

- Material leakage probe base : PE

- Cable : TPK (PVC Basis)

- Operating temperature : atmosphärisch

- Operating pressure : atmosphärisch

- media density : mit Schwimmer PE 52 ρ ≥ 1,05 g/cm³

- Switching hysteresis : typ. 2 mm

- Switching point tolerance : max. 2 mm

Resistance value

- Operational readiness : ca. 1 kΩ

- Leakage detection : ca. 12 kΩ

XR-6x0 | XR-6x1

Contact protection relay Measuring transducer

The contact protection relays are universal measuring transducers, which

input signals (resistance values) with "Namur" specification (DIN EN 60947).

Namur" specification (DIN EN 60947) into switching signals of floating

output contacts.

Protection class EN60529

- clamp : IP20

- Housing : IP40

Technical Data

- Operating temperature : -20...+60 °C

- Storage temperature : -30...+80 °C

- Output contacts : potentialfrei

- Switching voltage : min. 5 V, max. 250 V AC / 150 V DC

- Switching current : min. 5 mA, max. 5 A AC / 5 A DC

- Switching capacity : min. 300 mW, max.100 VA / max. 50 W

- CE marking : siehe Konformitätserklärung

- Ex-protection/IECEx : siehe Baumusterprüfbescheinigung

- Weight : ca. 170 g

- Quiescent current : umschaltbar

ELH 230 V

Hanging electrode as leakage probe 24...230 V AC/DC

The leakage probes of the type series ELH are approved by the "DIBt" for the monitoring of collecting chambers, collecting devices, inspection and filling shafts.

General data

- Protection class : IP 68

- Probe body material : PE, PVC, PPH, PVDF

- Diameter probe body : 15 mm, 25 mm, 40 mm

- Operating temperature : atmosphärisch

- Operating pressure : atmosphärisch

- Resistance value of line monitoring : 22 kΩ / 100 kΩ

Material

- Screw connection : PVDF

- Cable : TPK ( PVC Basis)

- on request : FEP (Teflon), PVC - blau

- cable length : auf Wunsch (Standard 3 m)

- Material Sensor rods : Edelstahl (1.4571), Hastelloy B, Hastelloy C, Titan, Tantal, Glas-Kohlestifte

SG2420

Supply unit SG2420 for flow sensor

The DSM-2420 sensor can only be operated in hazardous areas with the associated SG2420 power supply unit or appropriately designed, approved Zener barriers.

Properties

- Housing : Kunststoff

- Protection class : IP00

- Ambient temperature : -20…+60°C

- Supply voltage : 24V DC +20% / -10%

Fluidix Lub-VDT

Oil condition sensor for permanent monitoring of mechanical properties of liquids

The FluidIX Lub-VDT enables inline monitoring of mechanical fluid properties.

Properties

- CE marking : EN 61000-6-1/2/3/4

- Operating voltage : 9...32 V DC

- Housing material : Edelstahl

- Protection class : IP 67

- Dimensions : 30x90 mm

- Process connection : G 3/8"

- Electrical connection : M12-8 A-Coding

- Weight : 150g

- Measurement output : 2x 4...20mA

- bus protocol : ModbusRTU, CANopen

Measured variables

- Resonator frequency : 20...25 kHz

- Viscosity : 1-650 cSt (mm²/s)

- density : 0.5-1.5 g/cm³

- Temperature : -40...+125°C

- sampling rate : 1/s

Operating conditions

- Temperature of the fluid : -40...+125°C

- Housing temperature : -40...+100°C

- oil pressure : Max. 50 bar

- particle size : 250 μm

PPS-390

PPH float with magnet insert

for actuating monostable and bistable contacts

Variants

- 32 : AußenØ 26 x 180 mm, für RohraußenØ 32 u. 34 mm Gewicht ca. 38 g

- 37 : AußenØ 29,5 x 170 mm, für RohraußenØ 40 mm (PN 16) Gewicht ca. 62 g

- 40 : AußenØ 40 x 165 mm, für RohraußenØ 50 mm Gewicht ca. 145 g

- 50 : AußenØ 50 x 125 mm, für RohraußenØ 63 mm Gewicht ca. 156 g

ELH 24 V

Hanging electrode as leakage probe 24 V DC

The leakage probes of the type series ELH are approved by the "DIBt" for the monitoring of collecting chambers, collecting devices, inspection and filling shafts.

General data

- Protection class : IP 68

- Probe body material : PE, PVC, PPH, PVDF

- Diameter probe body : 15 mm, 25 mm, 40 mm

- Operating temperature : atmosphärisch

- Operating pressure : atmosphärisch

- Resistance value of line monitoring : 22 kΩ / 100 kΩ

Material

- Screw connection : PVDF

- Cable : TPK ( PVC Basis)

- on request : FEP (Teflon), PVC - blau

- cable length : auf Wunsch (Standard 3 m)

- Material Sensor rods : Edelstahl (1.4571), Hastelloy B, Hastelloy C, Titan, Tantal, Glas-Kohlestifte

ZMF-200e-IR

Robust gas sensor for industrial applications with extended operating temperature range and wide-ranging approvals

The ZMF-20X series includes sensors & transmitters for measuring gas concentrations of various gases such as CO2, methane, propane and SF-6.

This makes the sensors suitable for many applications. The ZMF-20X gas sensors are designed to be extremely rugged & suitable for use

in harsh environments.

Properties

- Operating conditions : -40 °C…+60 °C

- Storage conditions : -40 °C…+85 °C

- RelativeHumidity : 0…95 % nicht kondensierend

- Measurement method : NDIR (dual beam technology)

- Signal output : 4..20mA

- Power supply : 12…24 V DC

- Housing : Edelstahl

- Standard cable length : 1,5 m

- Certification : SIL2, ATEX (optional)

- pressure conditions : 800...1200 mbar

- screw thread : M46x1,5

Measuring ranges

- in ppm : in vol%

- 0…2.000ppm : 0…0,2 % vol

- 0…5.000ppm : 0…0,5 % vol

- 0…10.000ppm : 0…1 % vol

- 0…20.000ppm : 0…2 % vol

- 0…50.000ppm : 0…5 % vol

- 0…200.000ppm : 0…20 % vol

- 0…1.000.000ppm : 0…100 % vol

Measuring Accuracy

- below 25% of the range : ±1 % FS

- below 50% of the range : 2 % FS

- above 50% of the range : ±5 % FS

T204

Magnetic immersion probe made of stainless steel (1.4571)

For use with highly aggressive liquid media to detect level limit values in containers. Suitable for use in hazardous areas, zone 0 (category 1).

Properties

- connection : Polyesterdose | Aluminiumdose

- Protection class EN60529 : IP 65 Anschlussdose

- connection thread : G1 1/2" | G2"

- Sliding tube length : max. 6000 mm (Rohr Ø 12 mm)

- Operating pressure : max. 20 bar (Kugel) | max. 15 bar (Zylinder)

- Operating temperature : max. 135 °C

- Number of floats : max. 4

Float type

- Stainless steel ball 52mm ⌀ : Dichte: 0,75 g/cm³ | mind. Kontaktabstand: 75 mm

- Stainless steel ball 62mm ⌀ : Dichte: 0,65 g/cm³ | mind. Kontaktabstand: 85 mm

- Stainless steel cylinder 44 mm Ø : Dichte: 0,76 g/cm³ | mind. Kontaktabstand: 75 mm

Switching capacity

- Changeover contact : 60 W/VA

- normally open : 100 W/VA

- Normally closed contact : 60 W/VA

Switching current

- Changeover contact : max. 1 A

- NO/NC contact : max. 2 A

Contacts

- Changeover contact : 4

- normally open : 6

- Normally closed contact : 4

Our application engineers advise you personally, comprehensively and professionally!

Simply contact us by phone or e-mail!