Description

The FluidIX Lub-VDT enables inline monitoring of mechanical fluid properties.

Technical Data

Properties

- CE marking

- EN 61000-6-1/2/3/4

- Operating voltage

- 9...32 V DC

- Housing material

- Edelstahl

- Protection class

- IP 67

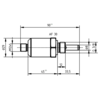

- Dimensions

- 30x90 mm

- Process connection

- G 3/8"

- Electrical connection

- M12-8 A-Coding

- Weight

- 150g

- Measurement output

- 2x 4...20mA

- bus protocol

- ModbusRTU, CANopen

Measured variables

- Resonator frequency

- 20...25 kHz

- Viscosity

- 1-650 cSt (mm²/s)

- density

- 0.5-1.5 g/cm³

- Temperature

- -40...+125°C

- sampling rate

- 1/s

Operating conditions

- Temperature of the fluid

- -40...+125°C

- Housing temperature

- -40...+100°C

- oil pressure

- Max. 50 bar*

- particle size

- 250 μm

- *higher pressure on request

Fluidix Lub-VDT application-specific configuration

Lub-VDT - [ 1 ] - [ 2 ]

Further product information

The compact sensor detects the viscosity and mass density of the surrounding medium on the basis of a low-frequency resonance sensor element. The high measuring accuracy and sensitivity is achieved by a robust and reliable quartz crystal tuning fork resonator. The sensor is long-term stable and is therefore particularly suitable for predictive maintenance and servicing strategies, such as oil condition monitoring. Even with changing process conditions (pressure, temperature, flow), excellent data quality is achieved due to the high measuring rate.

The sensor can be easily and cost-effectively integrated into existing machines and systems via digital and configurable analogue interfaces.

Documents and Downloads

Data sheet

Quick Start Guide

Mounting and installation instructions

Video of the product

Accessoires

Lub-VDT USB-Kit

go to productSimilar Products

FluidIX Lub-6

Inline-capable oil condition sensor based on a multi-channel infrared measuring cell for permanent monitoring of the oil condition and prevention of machine damage