Cart

TK-101 EX configure

AD-310 configure

MKL configure

TK-101 EX

Measuring transducer (R/I-transducer)

The measuring transducer Tk101 and Tk101Ex are built directly into the connection boxes of our Liquid Level Measuring Instruments of type TK-30.

Properties

- Operating temperature : -20...+60 °C

- Storage temperature : -40...+80 °C

- Ex-protection : siehe Zertifikat

- CE marking : siehe Konformitätserklärung

Input

- Resistance range in three-wire circuit : 4...10 kΩ

- Measuring current : 0,8 mA @ RE = 4 kΩ

- Measuring current : 0,33 mA bei RE = 10 kΩ

- Measuring voltage : 3,3 V

Supply/Output

- 2-wire : 4...20 mA

- Voltage(Um) : 11...28 V DC

- Burden / load : 0...800 Ω |RBürde max = [(Um - Um min) / 0,02] Ω

- Output signal in case of error : max. 24 mA

Fault influences

- Max. Total error : ± 1 %

- Temperature influence : -0,015 % / °C

- Supply voltage influence : 0,025 % / V

Setting range

- Full deflection : 60...105 %

- Zero point adjustment : 0...25 %

AD-310

programmable Digital Display

The programmable digital display AD-31… can be used in all applications through the parameterization capability of the input values and the display area.

Properties

- Protection class EN60529 clamp : IP 20

- Protection class EN60529 front panel : IP 65

- Operating temperature : – 20...+ 60 °C

- nominal voltage : Weitbereichsnetzteil; 20 V DC ... 230 V AC

- Power consumption : max. ca. 3 VA

- Output contact : 2 Schließer / NO

- Switching voltage : max. 250 V AC, 300 V DC

- Switching current : max. 3 A , DC min. 30 mA

- Switching capacity : max. 50W, 100 VA

- Unregulated auxiliary voltage source : 15...20 V DC / 20 mA

- Display : LED 14 mm, 5-stellig

- Dimensions : 96x48x100 mm

- Weight : ca. 200 g

- Panel cut-out : H:45+0,6mm, B:92+0,8 mm

Equipment

- Measuring input current : 0(4)...20 mA DC

- Measuring input voltage : 0(2)...10 V DC

- Measuring input Potentiometric voltage divider : 1...100 kΩ

- Display : LED 14 mm, 5-stellig

- operation : Folientasten

- Display range : -19999...32000

- data backup : EEPROM

- measurement uncertainty : ±1 % oder ±1 Digit

- analogue output : 0 (4)...20 mA

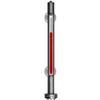

MKL

Magnetic Flap Indicator

The MKL level indicator is connected by its two connections to the container to be monitored (see connection example). According to the law of interconnected containers the level in the float chamber corresponds exactly to the level in the container

Properties

- connection : Flansch ab DN 15

- Material : rostfreier Edelstahl, PVC, PPH, PVDF

- Material flange : Edelstahl 1.4571, C22.8

- Material Float : Edelstahl, Titan, PVC, PPH, PVDF

- Number of contacts : beliebig

- Contact load : max 10 VA, max 230 V AC

- Display length : max. 6m

Operating temperature

- PTFE seal : max. 150 °C

- Stainless steel: Klingerit seal : max. 200 °C

- PVC : max. 60 °C

- PPH : max. 90 °C

- PVDF : max. 130 °C

Stainless steel float

- Weight : ~ 300 g

- Dimensions : Ø 52 x 270

- Operating pressure : 16 bar

- media density : ρ ≥ 0,70 g/cm³

Stainless steel float

- Weight : ~ 320 g

- Dimensions : Ø 52 x 270

- Operating pressure : 40 bar

- media density : ρ ≥ 0,75 g/cm³

Titanium float

- Weight : ~ 180 g

- Dimensions : Ø 52 x 150

- Operating pressure : 16 / 40 bar

- media density : ρ ≥ 0,73 g/cm³

PVC float

- Weight : ~ 331 g

- Dimensions : Ø 52 x 250

- Operating pressure : 6 bar

- media density : ρ ≥ 0,8 g/cm³

PPH float

- Weight : ~ 283 g

- Dimensions : Ø 52 x 250

- Operating pressure : 6 bar

- media density : ρ ≥ 0,69 g/cm³

PVDF float

- Weight : ~ 352 g

- Dimensions : Ø 52 x 250

- Operating pressure : 6 bar

- media density : ρ ≥ 0,85 g/cm³

ZDT-N

Differential pressure transmitter for low pressure applications

Versatile and reliable differential pressure transmitter for measurement on air and other non-aggressive media.

Properties

- Pressure type : Differenzdruck

- Housing : Kunststoff mit LCD-Anzeige (optional)

- Overpressure : 2,5* x Nenndruck

Measurement parameters

- Total error : ± 2,5 % FS (typ. ± 0,5 %)

- Linearity error : ± 1 % FS

- Signal output selection : 0...10 V 4...20 mA

- Pressure ranges (mbar) : 1/ 2 / 4 – 2,5 / 5 /10 – 12,5 / 25 /50 – 50 / 100 /200

Operating conditions

- Operating voltage (0...10V) : 14...30 V DC

- Operating voltage (4...20mA) : 12...30 V DC

- Operating temperature : 0...+50 °C

- Storage temperature : -20°C...+120°C

Connections

- Electrical connection : Schraubklemme im Gehäuse

- Process connection : Schlauchanschluss 3,5 mm oder 5,5 mm

Pressure measuring ranges

- 1/2/4mbar :

- 2,5/5/10mbar :

- 12,5/25/50mbar :

- 50/100/200mbar :

- other on request :

SG2420

Supply unit SG2420 for flow sensor

The DSM-2420 sensor can only be operated in hazardous areas with the associated SG2420 power supply unit or appropriately designed, approved Zener barriers.

Properties

- Housing : Kunststoff

- Protection class : IP00

- Ambient temperature : -20…+60°C

- Supply voltage : 24V DC +20% / -10%

T208

Immersible Magnetic Probe made of PVC, PE, PPH

Magnetic immersion probes for use with highly aggressive liquid media for detecting level limits in containers

Properties

- connection : Polyesterdose | Aluminiumdose

- Protection class EN60529 : IP 65 Anschlussdose

- Connector plug : 3- und 6-fach

- connection thread : G 1/8" | G 3/8" | G 1/4" | G 1/2" | G 1" | G1 1/4" | G1 1/2" | G2" | G3"

- connection cable : LiYY max. 80 °C | PTFE-Litze, 0,24 mm² | Silikon max. 150 °C

- Sliding tube length : max. 1000 mm (Rohr Ø 8 mm) | 6000 mm

- Operating pressure : max. 20 bar

- Viscosity : < 100 cp

- Protection class EN60529 : IP 68 Führungsrohr

- Switching voltage : max. 250 V

- Switching hysteresis : ca. 2...5 mm

- Holding range : ca. 12 mm

- Contact function : monostabil | bistabil

Operating temperature

- ltdata. : max. +60...+150 °C

- ltdata. : min. –20... –10 °C

- ltdata. : höhere oder niedrigere Temperaturen auf Anfrage

Switching capacity

- Changeover contact : 60 W/VA

- normally open : 100 W/VA

- Normally closed contact : 60 W/VA

Switching current

- Changeover contact : max. 1 A

- NO/NC contact : max. 2 A

Contacts

- Changeover contact : 8

- normally open : 10

- Normally closed contact : 7

Our application engineers advise you personally, comprehensively and professionally!

Simply contact us by phone or e-mail!