Cart

product added to request

product added to request

product added to request

MKL configure

QFS-2X configure

TK-307 configure

cIO CANopen Module

Compact I/O modules for DIN rail mounting

product series of compact CANopen I/O modules with various electrical connections

Properties

- Housing : Kunststoffgehäuse*

- Dimensions (LxBxH) : 18 x 90 x 62 mm

- Internal circuits : Ausgangsschutzschaltungen gegen Überspannung und elektrostasche Entladung

- Fieldbus and I/O level : getrennt durch galvanische Trennung

- ltdata.*zumAufrastenaufDIN-Trageschienen :

ElectricalConnection

- Operating voltage : 11...32V DC (typ. 24V DC)

- Operating temperature : 0...+55 °C

- Operating temperature : optional -40...+70 °C

- Conductor cross-section : 0,08...1,5 mm² (AWG28...AWG14)

CAN bus properties

- baud rate (max.) : 1 MBit

- ciA Standards : Ds301 Version 4.2 & DS401 Version 3.0

- ISO standards : ISO11898 (+ Transceiver TJA1050)

- PDO : siehe Dokumente

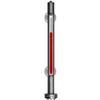

MKL

Magnetic Flap Indicator

The MKL level indicator is connected by its two connections to the container to be monitored (see connection example). According to the law of interconnected containers the level in the float chamber corresponds exactly to the level in the container

Properties

- connection : Flansch ab DN 15

- Material : rostfreier Edelstahl, PVC, PPH, PVDF

- Material flange : Edelstahl 1.4571, C22.8

- Material Float : Edelstahl, Titan, PVC, PPH, PVDF

- Number of contacts : beliebig

- Contact load : max 10 VA, max 230 V AC

- Display length : max. 6m

Operating temperature

- PTFE seal : max. 150 °C

- Stainless steel: Klingerit seal : max. 200 °C

- PVC : max. 60 °C

- PPH : max. 90 °C

- PVDF : max. 130 °C

Stainless steel float

- Weight : ~ 300 g

- Dimensions : Ø 52 x 270

- Operating pressure : 16 bar

- media density : ρ ≥ 0,70 g/cm³

Stainless steel float

- Weight : ~ 320 g

- Dimensions : Ø 52 x 270

- Operating pressure : 40 bar

- media density : ρ ≥ 0,75 g/cm³

Titanium float

- Weight : ~ 180 g

- Dimensions : Ø 52 x 150

- Operating pressure : 16 / 40 bar

- media density : ρ ≥ 0,73 g/cm³

PVC float

- Weight : ~ 331 g

- Dimensions : Ø 52 x 250

- Operating pressure : 6 bar

- media density : ρ ≥ 0,8 g/cm³

PPH float

- Weight : ~ 283 g

- Dimensions : Ø 52 x 250

- Operating pressure : 6 bar

- media density : ρ ≥ 0,69 g/cm³

PVDF float

- Weight : ~ 352 g

- Dimensions : Ø 52 x 250

- Operating pressure : 6 bar

- media density : ρ ≥ 0,85 g/cm³

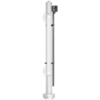

QFS-2X

Stainless Steel Float Switch

QFS-20 & QFS-21 float switches have stainless steel floats and one or two reed contacts.

Properties

- Protection class EN60529 : IP68

- Material Float : VA 1.4571

- Material hose : Edelstahlwellschlauch (1.4404) mit Edelstahldrahtumflechtung (1.4301)

- Operating temperature : max. + 150 °C

- media density : ρ ≥ 0,8g/cm³

- Switching system : Reed-Schalter

- Contact : Wechsler, NO, NC

- Switching voltage : 4...250 V AC/DC

- Switching current : 1 mA ...1 A

- Switching capacity : max. 1A, 60 VA/60 W

- Switching hysteresis : ca. 100 mm

- Switching angle : ca. + 20° / – 20°

- Operating pressure (QFS-20) : max. 15 bar

- Operating pressure (QFS-21) : max. 6 bar

CSC-20 YUGO

Decentralised control unit, equipped with a CO2 sensor for needs-based ventilation

Decentralised CO2 monitoring with direct control of various supply and exhaust air elements such as fans and dampers (0..10.000 ppm)

Properties

- Power supply : 230 V AC

- measuring range (CO2) : 0..10.000 ppm

- Measuring accuracy CO2 : ± 50ppm +3 % vom Messwert

- Operating conditions : 0…50°C / 0…85 %rH

- Storage conditions : -30…70°C / 0…85 %rH

- Protection class : IP 31

- EMV/ESD : EN 50082-1, EN 50082-2

- Signal output : I²C

TK-307

Stainless steel level sensor

T30... continuous magnetic immersible probes are used for quasi-acquisition of the filling level in containers with liquid media.

Technical Data

- Connection housing : Aluminium H 30 mm x B 50 mm x T 45 mm

- Connection socket : Polyester H 55 mm x B 80 mm x T 45 mm

- Protection class socket / plug : IP 65

- Sliding tube length : max. 6000 mm

- Operating temperature : max. 130 °C

- Resolution depending on type : 7,5 mm | 10 mm | 15 mm | 20 mm | 1% | 2% | 5%

- Mounting : 2 Schlauchschellen

- Accessories : R/I-Wandler TK-101

BK-3X0

Bistable change-over contact

Magnetically actuated changeover switch,

which permanently changes its electrical switching state as a result of a magnetic system passing by, depending on the direction of movement.

Properties

- Protection class EN60529 : IP 65

- Operating temperature : –25...+70 °C

- Wire cross-section max. : 1,5mm²

- Switching point distance between two contacts : min. 40 mm

- Switching hysteresis : ca. 10-15 mm

Material

- Housing : Polycarbonat

- Mounting clip : V2A, Kabelbinder (PP)

- Rivet : V2A

- Screw connection : M 20 x 1.5, Polyamid

Weight

- BK-390-50 : 137 g

- BK-390-63 / BK-380 : 140 g

Switching contact

- Switching voltage : 5...250 V AC/DC

- Switching current : 1mA...6 A AC/DC

- Switching capacity(min.) : 300 VA, 60 W

- Switching capacity(max.) : 5 mW

T204

Magnetic immersion probe made of stainless steel (1.4571)

For use with highly aggressive liquid media to detect level limit values in containers. Suitable for use in hazardous areas, zone 0 (category 1).

Properties

- connection : Polyesterdose | Aluminiumdose

- Protection class EN60529 : IP 65 Anschlussdose

- connection thread : G1 1/2" | G2"

- Sliding tube length : max. 6000 mm (Rohr Ø 12 mm)

- Operating pressure : max. 20 bar (Kugel) | max. 15 bar (Zylinder)

- Operating temperature : max. 135 °C

- Number of floats : max. 4

Float type

- Stainless steel ball 52mm ⌀ : Dichte: 0,75 g/cm³ | mind. Kontaktabstand: 75 mm

- Stainless steel ball 62mm ⌀ : Dichte: 0,65 g/cm³ | mind. Kontaktabstand: 85 mm

- Stainless steel cylinder 44 mm Ø : Dichte: 0,76 g/cm³ | mind. Kontaktabstand: 75 mm

Switching capacity

- Changeover contact : 60 W/VA

- normally open : 100 W/VA

- Normally closed contact : 60 W/VA

Switching current

- Changeover contact : max. 1 A

- NO/NC contact : max. 2 A

Contacts

- Changeover contact : 4

- normally open : 6

- Normally closed contact : 4

Our application engineers advise you personally, comprehensively and professionally!

Simply contact us by phone or e-mail!