Cart

ZMF-203e-IR configure

LU-150 configure

T-200.L Ex configure

HD-110 | HD-112 | HD-114 configure

XR-4x0 | XR-4x1 configure

TK-315 configure

LU-180 EX configure

HD-100 | HD-102 | HD-104 configure

W-35X configure

EE-2X configure

TK-312 configure

ZMF-203e-IR

Robust sulphur hexafluoride SF6 sensor for industrial applications with extended operating temperature range and wide-ranging approvals

The ZMF-203e-IR is an SF6 sensor for measuring sulphur hexafluoride concentration in harsh environments.

Properties

- Operating conditions : -40 °C…+60 °C

- Storage conditions : -40 °C…+85 °C

- RelativeHumidity : 0…95 % nicht kondensierend

- Measurement method : NDIR (dual beam technology)

- Certification : SIL2, ATEX

- Signal output : 4..20mA

- Power supply : 12…24 V DC

- Housing : Edelstahl

- Standard cable length : 1,5 m

- pressure conditions : 800...1200 mbar

- screw thread : M46x15

Measuring ranges

- in ppm : in vol%

- 0...1.000ppm : 0...0,1 vol%

- 0...2.000ppm : 0...0,2 vol%

Options

- Other cable lengths on request :

- ATEX certification (optional) :

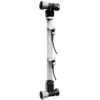

LU-150

Compact Ultrasonic Level Sensor

The LU-150 is a short-range integrated ultrasonic level transmitter, intrinsically safe as Ex-version LU-180. This general purpose, 2 wire, 4 to 20 mA loop powered transmitter is ideal for liquids, slurries, and bulk materials in open or closed vessels to 5 m (16.4 ft).

Properties

- Protection class EN60529 : IP 68

- Power supply : 12...30 V DC / 0.1A Spitze

- Power consumption : Max. 0,75 W (25 mA bei 24 V DC)

- Output : 4...20 mA

- Max. Load : 600 Ω bei 24 V DC

- Measuring span : Proportional oder umgekehrt proportional

- Measurable materials : Flüssigkeiten, Schlämme, Schuttgüter

- operating temperature : –20...+60 °C

- Opening angle : 12°

- working pressure : Atmosphärisch

- Display : 3-stelliges LCD

- Process connection : Gewinde G 2" (BSPP) EN 10226 PVDF

- Weight : 1,3 Kg

- Cable entry : Kabelverschraubung M 20 x 1.5

- Material housing electronics : Polybutylenterephthalat PBT

- Material sensor / thread : PVDF-Copolymer

Input

- Measuring range : 0,25...5,0 m

- frequency : 54 kHz

Measuring Accuracy

- Measurement deviation : ± 0,25 % vom Messbereich (in Luft)

- Resolution : 3 mm

- Temperature compensation : im Sensor integriert

- Echo processing : „Sonic Intelligence“ von Siemens

T200

Immersible Magnetic Probe made of PVC, PE, PPH, PTFE or stainless steel (1.4571)

Magnetic immersion probes for use with highly aggressive liquid media for detecting level limits in containers

Properties

- connection : Polyesterdose | Aluminiumdose

- Protection class EN60529 : IP 65 Anschlussdose

- Connector plug : 3- und 6-fach

- connection thread : G 1/8" | G 3/8" | G 1/4" | G 1/2" | G 1" | G1 1/4" | G1 1/2" | G2" | G3"

- connection cable : LiYY max. 80 °C | PTFE-Litze, 0,24 mm² | Silikon max. 150 °C

- Sliding tube length : max. 1000 mm (Rohr Ø 8 mm) | 6000 mm

- Operating pressure : max. 20 bar

- Viscosity : < 100 cp

- Protection class EN60529 : IP 68 Führungsrohr

- Switching voltage : max. 250 V

- Switching hysteresis : ca. 2...5 mm

- Holding range : ca. 12 mm

- Contact function : monostabil | bistabil

Operating temperature

- ltdata. : max. +60...+150 °C

- ltdata. : min. –20... –10 °C

- ltdata. : höhere oder niedrigere Temperaturen auf Anfrage

Switching capacity

- Changeover contact : 60 W/VA

- normally open : 100 W/VA

- Normally closed contact : 60 W/VA

Switching current

- Changeover contact : max. 1 A

- NO/NC contact : max. 2 A

Contacts

- Changeover contact : 8

- normally open : 10

- Normally closed contact : 7

T-200.L Ex

Leakage probes with general building authority approval for hazardous areas

The leakage probes T-200.L are approved by the "DIBt" on the basis of the "WasBauPVO" for the detection of leaking water-polluting liquids. The T-200.L Ex may be used as leakage probes in hazardous areas, zone 1 (category 2).

Connection

- Box : Ex-Polyesterdose (PO)

Properties

- Protection class : IP 65

- Cable entry : PVDF-Verschraubung, PVC-Dichtung

- Material Float : PE

- Material leakage probe base : PE

- Cable : TPK (PVC Basis)

- Operating temperature : atmosphärisch

- Operating pressure : atmosphärisch

- media density : mit Schwimmer PE 52 ρ ≥ 1,05 g/cm³

- Switching hysteresis : typ. 2 mm

- Switching point tolerance : max. 2 mm

Resistance value

- Operational readiness : ca. 1 kΩ

- Leakage detection : ca. 12 kΩ

- Switching time : ca. 20 ms

HD-110 | HD-112 | HD-114

Hydrostatic screw-in probes (4...20mA | 0.8...10mWS)

Continuous and precise level measurement in unpressurised, open basins and tanks as well as underground applications such as shafts, wells and boreholes.

Properties

- Protection class EN60529 : IP 65

- Operating temperature : -10...70 °C

- Storage temperature : -25...70 °C

- Power supply : 15...30 V DC

- power : max. 25 mA

- Output : 2-Leiter-Technik | 4...20 mA

- Measuring range : 0,8...10 mWs (Standard)

- Overpressure : ca. 20 %

- Deviation from characteristic curve : Nichtlinearität,

- Insulation resistance : > 100 kΩ

- Short-circuit resistance : permanent

- Reverse polarity protection : keine Schädigung o. Funktion bei vertauschten Anschlüssen

Materials

- Housing : Edelstahl 1.4571, PVC, PVDF

- Measuring cell : Edelstahl 1.4404, Keramik AI2o3 96%, Keramik AI2o3 99,9%

- Seals : FKM (Viton ®), EPDM, FFKM (Kalrez ®)

- connection thread : G ¾“ | G 1 ½“

- Plug : Steckverbindung DIN 43650

XR-4x0 | XR-4x1

Electrode relay with ATEX

The electrode relays are used for conductive level detection.

levels. The possible applications extend

areas where conductive, liquid media are to be detected, controlled

to be detected, controlled or regulated. Hereby

level detection (overflow / dry run) as well as minimum / maximum

as well as minimum / maximum controls can be realised.

Protection class EN60529

- clamp : IP20

- Housing : IP40

Technical Data

- Operating temperature : -20...+60 °C

- Storage temperature : -30...+80 °C

- Output contacts : potentialfrei

- Switching voltage : min. 5 V | max. 250 V AC / 150 V DC

- Switching current : min. 5 mA | max. 5 A AC / 5 A DC

- Switching capacity : min. 300 mW | max. 100 VA / 50 W

- Quiescent current : umschaltbar

- Weight : ca. 250 g

- CE marking : siehe Konformitätserklärung

- Ex-protection/IECEx : siehe Prüfbescheinigung

TK-315

Evaluation unit with 4 limit contacts (NO-contacts)

The TK-315 limit comparator can be used in conjunction with our TK-30... continuous level sensors with 0(4)...20 mA or 0...10 V output signal for level control/measurement.

Properties

- Protection class EN60529 clamp : IP 20

- Protection class EN60529 front panel housing : IP 40

- Operating temperature : –20...+60 °C

- nominal voltage : 24... 230 V AC/DC

- Power consumption : 2 VA

- Dimensions housing type B : 22,5 x 114,5 x 99 mm

- Dimensions housing type C : 22,5 x 114,5 x 114 mm

Input

- power : 0/4...20 mA

- Voltage : 0...10 V

- Resistance in three-wire circuit RG : 0–4...10 kΩ

Output

- Output contacts : 4 Schließerkontakte

- Switching voltage : max. 250 V AC

- Switching current : max. 3 A

- Switching capacity : max. 500 VA

- Temperature influence tolerance : max. ± 0,6 % der Signalspanne

- Mounting : Tragschiene nach EN 50022

- Current output : 4...20 mA bezogen auf die Masse des Eingangs

- Display (%) : 2-stellig, 7-Segment

- Weight : 175 g

LU-180 EX

Compact Ultrasonic Level Sensor

The LU-150 is a short-range integrated ultrasonic level transmitter, intrinsically safe as Ex-version LU-180. This general purpose, 2 wire, 4 to 20 mA loop powered transmitter is ideal for liquids, slurries, and bulk materials in open or closed vessels to 5 m (16.4 ft).

Properties

- Protection class EN60529 : IP 68

- Power supply : 12...30 V DC / 0.1A Spitze

- Power consumption : Max. 0,75 W (25 mA bei 24 V DC)

- Output : 4...20 mA

- Max. Load : 600 Ω bei 24 V DC

- Measuring span : Proportional oder umgekehrt proportional

- Measurable materials : Flüssigkeiten, Schlämme, Schuttgüter

- operating temperature : –20...+60 °C

- Opening angle : 12°

- working pressure : Atmosphärisch

- Display : 3-stelliges LCD

- Process connection : Gewinde G 2" (BSPP) EN 10226 PVDF

- Weight : 1,3 Kg

- Cable entry : Kabelverschraubung M 20 x 1.5

- Material housing electronics : Polybutylenterephthalat PBT

- Material sensor / thread : PVDF-Copolymer

Input

- Measuring range : 0,25...5,0 m

- frequency : 54 kHz

Measuring Accuracy

- Measurement deviation : ± 0,25 % vom Messbereich (in Luft)

- Resolution : 3 mm

- Temperature compensation : im Sensor integriert

- Echo processing : „Sonic Intelligence“ von Siemens

HD-100 | HD-102 | HD-104

Hydrostatic immersion probes (0.8...10mWS)

Continuous and precise level measurement in unpressurised, open basins and tanks as well as underground applications such as shafts, wells and boreholes.

Properties

- Protection class EN60529 : IP68

- Operating temperature : -10...70 °C (PVC: -10...60 °C)

- Storage temperature : -25...70 °C (PVC: -10...60 °C)

- Power supply : 15...30 V DC

- power : max. 25 mA

- Output : 2-Leiter-Technik

- Measuring range : 0,8...10 mWs (Standard)

- Overpressure : abhängig vom Messbereich

- Deviation from characteristic curve : Nichtlinearität,

- Insulation resistance : > 100 kΩ

- Short-circuit resistance : permanent

- Reverse polarity protection : keine Schädigung o. Funktion bei vertauschten Anschlüssen

Materials

- Housing : Edelstahl 1.4571, PVC, PVDF

- Measuring cell : Edelstahl 1.4404, Keramik Al2o3 96%, Keramik Al2o3 99,9%

- Seals : FKM (Viton ®), EPDM, FFKM (Kalrez ®)

- Cable : PVC, PUR, FEP (Ø8 mm; 2 x 0,25 mm2 mit Luftschlauch und PTFE-Filter

FDL400

Flow Data Logger

The FDL400 "Flow Data Logger 400" measuring device is suitable for measuring the flow of water and wastewater in fully or partially filled sewers or pipes of various geometries.

Properties

- Housing : Aluminium

- Protection class : IP30

- Dimensions : 197 x 153 x 37,5mm (B x H x T)

- Temperature range : 0 – 50°C

- Supply voltage : 24V DC +/-20%

- Power consumption : 120mA – 220mA

- Reverse polarity protection : ✓

- Display : 4x20

Outputs

- analog 0(4)–20mA : 3x

- digital : 4x

- fixed for alarm : 1x

- free configurable : 3x

display of measured value

- Flow velocity :

- Filling level :

- flow :

- flow rate :

W-35X

Water Level Gauge with sight glass indicator

The water level gauge is particulary suitable for all liquid media which are aggressively hot and rapidly moved in a container, but are not too much contamined.

Properties

- Tank connection : Flansch ab DN 25 oder Verschraubung ab G ½"

- Material Float : PPH max. 2,5 bar, Glas max. 10 bar

- cable length : bei monostabilem Kontakt: Standard 2 m

- Number of contacts : beliebig

- Contact distance : min. 10 mm

- Temperature of the fluid : mit Plexiglasrohr max. +70 °C

- media density : ρ ≥ 0,95 g/cm³ | ρ ≥ 0,85 g/cm³ (auf Wunsch)

Properties W-350

- Material tube sight glass : transparentes PVC

- Temperature of the fluid : max. +60 °C

- Operating pressure : max. 2,5 bar

- Material flange : PVC

- Material connection with angle valve : PVC

- Material sealing ring : Gummi

Properties W-351

- Material tube sight glass : Hartglas, Plexiglas

- Temperature of the fluid : max. +120 °C

- Material flange : Rotguss

- Material connection with angle valve : Rotguss

- Material sealing ring : Silikon

- Operating pressure with glass tube : max. 10 bar

- Operating pressure with plexiglass tube : max. 2 bar

Properties W-352

- Material tube sight glass : Hartglas, Plexiglas

- Temperature of the fluid : max. +120 °C

- Material flange : Edelstahl

- Material connection with angle valve : Edelstahl 1.4571 als Bogen 90°

- Material sealing ring : PTFE und Viton

- Operating pressure with glass tube : max. 10 bar

- Operating pressure with plexiglass tube : max. 2 bar

Properties W-353

- Material tube sight glass : Hartglas, Plexiglas

- Temperature of the fluid : max. +120 °C

- Material flange : Edelstahl

- Material connection with angle valve : Edelstahl 1.4401

- Material sealing ring : PTFE und Viton

- Operating pressure with glass tube : max. 10 bar

- Operating pressure with plexiglass tube : max. 2 bar

EE-2X

electrode, multiple for Ex-Zone 0 (Cat. 1)

The conductive electrodes of the EE-21/EE-22 series enable the monitoring of conductive liquids within the Ex area Zone 0 (Cat. 1).

Variants

- cable connection on side : EE-21

- cable connection on top : EE-22

Properties

- connection : Edelstahl (1.4571)

- Protection class EN60529 : IP65

- Ex-protection : TÜV 02 ATEX 1796 X

- Ex protection type : II 1 G Ex ia IIC T6 bzw. Ex ia IIB T6 / II ½ G Ex ia IIC T6 bzw. Ex ia IIB T6

- connection thread : G1" | G1¼"

- Cable entry EE-21 : Edelstahl (1.4571)

- Cable entry EE-22 : Kunststoff

- Rod diameter : 4 mm | 6 mm

- rod length : max. 6.000 mm

- Operating pressure media side : max. 40 bar

- Spacer : ab Länge > 1000 mm je 1 pro 1000 mm

Material

- electrode body : Edelstahl (1.4571)

- Seal (head) : Viton

- Seal (media side) : Viton | PTFE

- Potential equalisation conductor connection : Edelstahl (1.4571)

- electrode rods : Edelstahl (1.4571) | Hastelloy C | Tantal

- Coating : PTFE

Operating temperature

- Category 1 Class T6...T1 : 60 °C

- Category 2 Class T6 : 80 °C

- Category 2 Class T5 : 95 °C

- Category 2 Class T4 : 130 °C (100°C)

- Category 2 Class T3...T1 : 150 °C (100°C)

HD-1XX

Hydrostatic filling level measurement

Continuous and precise level measurement in unpressurised, open basins and tanks as well as underground applications such as shafts, wells and boreholes.

TK-312

Evaluation unit with 0/4... 20 mA current output

The TK-312 measuring transducer converts the resistance signal supplied from a continuous level sensor into a current signal proportionate to the level.

Properties

- Protection class EN60529 clamp : IP 20

- Protection class EN60529 front panel housing : IP 40

- Operating temperature : –20...+60 °C

- nominal voltage : 24... 230 V AC/DC

- Power consumption : 2 VA, 2W

- Dimensions housing type B : 22,5 x 114,5 x 99

- Dimensions housing type C : 22,5 x 114,5 x 114

Input

- Voltage : 0...10 V

- Resistance in three-wire circuit RG : 0-4...10 kW

Output

- Temperature influence tolerance : max. ± 0,6 % der Signalspanne

- Current output : 0/4... 20 mA bezogen auf die Masse des Eingangs

- Voltage output : 0/2... 10 V

- Mounting : Tragschiene nach EN 50022

- Weight : 175 g

Our application engineers advise you personally, comprehensively and professionally!

Simply contact us by phone or e-mail!