Cart

product added to request

Get an offer

QFS-3X configure

TK-309-0 configure

GSB-390 configure

TK-307-0 configure

QFS-55 configure

EP configure

MTA configure

QFS-5x | QFS-6x configure

ZT-N configure

PPS-390 configure

VS-D250 configure

TSR-CAN-03 configure

NP-256 configure

QFS-3X

Mercury-free float switch with µ-switch

Properties

- Protection class EN60529 : IP 68

- Cable entry : PVC , PTFE bzw. PVDF

- Conductor cross-section : 3 x 0,75 mm², PUR 3x 0,5mm²

- Operating pressure cylinder : max. 1 bar

- Operating pressure sphere : max. 2 bar

- Switching system : µ-Schalter

- Contact : Wechsler, NO, NC

Material Float

- QFS-30 : PPH (Polypropylen)

- QFS-31 : PPH (Polypropylen)

- QFS-34 : PE (Polyethylen)

Cable

- TPK : PVC Basis Ø 5,9 mm

- TPKV : PVC verstärkt Ø 7,3 mm

- PUR : Polyurethan Ø 5,4 mm

- SIL : Silikon Ø 6,4 mm

- FEP : Teflon Ø 4,0 mm

- AEM : Ethylen-Acrylat-Kautschuk

Cable length between float & attachment

- TPK : 70 mm

- TPKV : 90mm

- PUR : 100mm

- SIL : 80 mm

- FEP : 110 mm

- AEM : abhängig vom Innenkabel

Operating temperature

- TPK(V), AEM : max. + 60 °C

- PUR : max. + 70 °C

- Silicone,Tefloncable with PE float : max. + 80 °C

- Silicone, Teflon cable with PP float : max. + 85 °C

MaterialDensity

- QFS-31 : ≥≥ 0,6 g/cm³

- QFS-34 : ≥≥ 0,75 g/cm³

- QFS-30 TPK(V) cable : ≥≥ 0,85 g/vcm³

- QFS-30 PUR cable : ≥≥ 0,95 g/cm³

- QFS-30 SIL cable : ≥≥ 0,90 g/cm³

- QFS-30 FEP cable : ≥≥ 0,95 g/cm³

- QFS-30AEM cable : ≥≥ 0,90 g/cm³

TK-309-0

Stainless steel level sensor for Ex-Zone 0 (Cat.1)

T30... continuous magnetic immersible probes are used for quasi-acquisition of the filling level in containers with liquid media.

Technical Data

- Protection class Socket : IP65

- Float type : Typ 07

- Sliding tube length : max. 6000 mm

- Operating temperature : max. 135 °C

- Operating pressure : max. 20 bar

- media density : Typ 07: 0,54 g/cm³

- Resolution : 7,5 mm | 10mm |15 mm | 20 mm

- Accessories : R/I-Wandler TK-101

GSB-390

Glass float with magnet insert

for actuating monostable and bistable contacts

Variants

- 150 : AußenØ 26,5 x 150 mm (2 Magnete für monostabile Kontakte) Gewicht ca. 50 g

- 190 : AußenØ 26,5 x 190 mm (2 Magnete für monostabile Kontakte) Gewicht ca. 61 g

- 205 : AußenØ 26,5 x 205 mm (3 Magnete auch für bistabile Kontakte) Gewicht ca. 69 g

TK-307-0

Stainless steel level sensor for Ex-Zone 0 (Cat.1)

T30... continuous magnetic immersible probes are used for quasi-acquisition of the filling level in containers with liquid media.

General data

- Connection aluminium box : H30 x B50 x T45 mm

- Connection polyester box : H56 x B80 x T75 mm

- connection cable : 1000 mm PUR blau

- Protection class Socket : IP65

- Material Sliding tube : VA 1.4571

- Material of the angle fastening : VA 1.4408

- Sliding tube length : max. 6000 mm

- Operating temperature : max. 130 °C

- Resolution : 7,5 mm | 10 mm | 15 mm | 20 mm

- Mounting : 2 Schlauchschellen

- Accessories : R/I-Wandler TK-101

LGW-13

CO2 sensor for measuring room air quality with visual and acoustic warning signal output

Multifunctional CO2 sensor with LED display and acoustic alarm, equipped with switching functions for both industrial and private applications (0...3.000ppm)

Product features

- Product type : CO2-Sensor zur Bewertung und Überwachung der Luftgüte

- Measuring principle : Basierend auf optischem Messprinzip (NDIR)

- Measuring range : Lieferbar in unterschiedlichen Messbereichen (Standard 0…3.000ppm)

- Display : Darstellung der CO2-Konzentration mittels Bargraphanzeige (Luftgüteampel)

- Switching output : Einstellbarer potentialfreier Schaltausgang

- Signal output : 4...20 mA und 0...10 V Signalausgang (nur bei der Variante L)

- Alarm : Akustischer Alarmmelder (je nach eingestellten CO2-Grenzwerten)

- further function : Integrierte Funktionsüberwachung

- Housing : Kompaktes IP 20 Wandgehäuse (Polycarbonat, weiß)

- Extension : Mögliche Erweiterung um Temperaturmessung

- Assembly : Erhältlich als Tischgerät mit Netzteil oder zur Wand- & Aufputzmontage ohne Netzteil

Technical specifications

- Standard measuring range: : 0…3.000ppm

- Optional measuring ranges: : 0…1% vol, 0…3% vol (weitere auf Anfrage)

- Accuracy : +-3% vom Messbereich (30 ppm bei 3.000 ppm)

- Relay output: : Potentialfrei

- Response time : ca. 20 s

- Operating voltage : 24 V DC, 150 mA

QFS-55

Teflon float switch in rod design

The float switch combination is built with float switches of the QFS-50 and QFS-60 series. This makes it possible to control a level in a simple way.

Technical Data

- Material : PTFE (Teflon)

- connection cable : Silikon, Teflon

- Material rod : VA-Rohr, PTFE beschichtet

- Operating temperature : max. +150 °C

- media density : ρ ≥ 0,75 g/cm³

- Switching system : Reed-Schalter

- Contact : Wechsler, NO, NC

- Inductive/capacitive loads : Unbedingt Kontaktschutz vorsehen

- Ex-protection optional : Elektrische Daten siehe EG-Prüfbescheinigung IBExU10ATEX 1089

Reed contact

- Switching current : 1 mA ... 1 A

- Switching voltage : 24 ... 250 V AC/DC

- Switching capacity : Max. 1A, 60 VA / 60 W

- Switching hysteresis : ca. 100 mm

- Switching angle : ca. +20°...–20°

Namur circuit (1kΩ/12kQ)

- Switching current / switching voltage : nur zum Anschluss an KR-163... oder andere „Namur”-Relais

- Switching hysteresis : ca. 100 mm

- Switching angle : ca. +20°...–20°

Lub-VDT USB-Kit

Software and USB kit for configuration & evaluation

Properties

- details : folgen

EP

Plate Electrode as Leak Detector (conductive)

with general approval for constructions and EC-Type-Examination Certificate for Ex-zone 1(Cat. 2)

Properties

- Protection class EN60529 : IP 68

- Operating temperature : atmosphärisch

- Operating pressure : atmosphärisch

- Resistance value of line monitoring : 22 kΩ / 100 kΩ

- cable length : auf Wunsch

Material

- Cable : TPK (PVC Basis)

- Sensor rods : Edelstahl (1.4571) | Hastelloy B | Hastelloy C | Titan | Tantal | Glaskohlenstoff

Options

- cable material : FEP (Teflon) | EX (PVC blau)

MTA

Mechanical tank level indicator

The tank level indicator is a mechanically actuated indication operating "on the spot”. It permits a high degree of safety and flexibility thanks to separate points of measurement and indication.

Properties

- Tank connection : Flansch ab DN 80 (Sonderanschlüsse auf Wunsch)

- Material : siehe Maßbild

- Material Tube : PVC, transparent | Ø 50 x 1,8 | Ø 63 x 3,0

- Operating temperature : –20...+60 °C

- Operating pressure : atmosphärisch

Material Float

- PPH : Ø 70 mm 460 g

- PVC : Ø 70 mm 455 g

- PPH : Ø 40 mm 370g

- PE : Ø 70 mm ca. 450 g

Material Rope

- PPH : (rot, Ø 2 mm) ~ 2 g/m

- Polyester : (bunt, Ø 2 mm) ~ 4 g/m

- PTFE : (weiss, Ø 3 mm) ~ 10 g/m

QFS-5x | QFS-6x

Teflon float switch for all kinds of liquids up to 150°C

The float of the QFS-50 and QFS-60 float switches is made of Teflon. Inside the float, one or two reed contacts with a movable permanent magnet are inserted as a switching element.

Technical Data

- Material : PTFE (Teflon)

- connection cable : Silikon, Teflon

- Operating temperature : max. +150°C

- Operating pressure : 1 bar

- media density : ρ ³ 0,75 g/cm³

- Switching system : Reed-Schalter

- Contact : Wechsler, NO, NC

- Inductive/capacitive loads : Unbedingt Kontaktschutz vorsehen

- Ex-protection optional : Elektrische Daten siehe EG-Prüfbescheinigung IBExU10ATEX 1089

Reed contact

- Switching current : 1 mA ... 1 A

- Switching voltage : 24 ... 250 V AC/DC

- Switching capacity : Max. 1A, 60 VA / 60 W

- Switching hysteresis : ca. 100 mm

- Switching angle : ca. +20°...–20°

Namur circuit (1kΩ/12kQ)

- Switching current / switching voltage : nur zum Anschluss an KR-163... oder andere „Namur”-Relais

- Switching hysteresis : ca. 100 mm

- Switching angle : ca. +20°...–20°

T-20X

Immersible Magnetic Probe made of PVC, PE, PPH, PTFE or stainless steel (1.4571)

Magnetic immersion probes for use with highly aggressive liquid media for detecting level limits in containers

Properties

- connection : Polyesterdose | Aluminiumdose

- Protection class EN60529 : IP 65 Anschlussdose

- Connector plug : 3- und 6-fach

- connection thread : G 1/8" | G 3/8" | G 1/4" | G 1/2" | G 1" | G1 1/4" | G1 1/2" | G2" | G3"

- connection cable : LiYY max. 80 °C | PTFE-Litze, 0,24 mm² | Silikon max. 150 °C

- Sliding tube length : max. 1000 mm (Rohr Ø 8 mm) | 6000 mm

- Operating pressure : max. 20 bar

- Viscosity : < 100 cp

- Protection class EN60529 : IP 68 Führungsrohr

- Switching voltage : max. 250 V

- Switching hysteresis : ca. 2...5 mm

- Holding range : ca. 12 mm

- Contact function : monostabil | bistabil

Operating temperature

- ltdata. : max. +60...+150 °C

- ltdata. : min. –20... –10 °C

- ltdata. : höhere oder niedrigere Temperaturen auf Anfrage

Switching capacity

- Changeover contact : 60 W/VA

- normally open : 100 W/VA

- Normally closed contact : 60 W/VA

Switching current

- Changeover contact : max. 1 A

- NO/NC contact : max. 2 A

Contacts

- Changeover contact : 8

- normally open : 10

- Normally closed contact : 7

ZT-N

Customisable low pressure sensor for precise measurement of the smallest pressures

Reliable low pressure sensor in a robust and compact design

Properties

- Pressure type : Relativdruck | Absolutdruck

- Housing : Edelstahl

- Overpressure : 1,5* fach bis 400 bar, darüber 1,2* fach

- Bursting pressure : 3* fach bis 600 bar, darüber 1,5* fach

Measurement parameters

- response time : < 1 ms

- Total error : ≤ 0,5 % FS

- Non-linearity : ≤ 0,2 % FS

- Non-repeatability : ≤ 0,10 % FS

- Hysteresis : ≤ 0,15 % FS

ambient conditions

- Temperature of the fluid : -40...+125 °C (0...+80 °C kompensierter Bereich)

- Ambient temperature : -40...+105 °C

- Storage temperature : -40...+125°C

- Shock resistance : g 1000 gemäß IEC 60068-2-32

- Vibration resistance : g 20 gemäß IEC 60068-2-6

ZDT-N

Differential pressure transmitter for low pressure applications

Versatile and reliable differential pressure transmitter for measurement on air and other non-aggressive media.

Properties

- Pressure type : Differenzdruck

- Housing : Kunststoff mit LCD-Anzeige (optional)

- Overpressure : 2,5* x Nenndruck

Measurement parameters

- Total error : ± 2,5 % FS (typ. ± 0,5 %)

- Linearity error : ± 1 % FS

- Signal output selection : 0...10 V 4...20 mA

- Pressure ranges (mbar) : 1/ 2 / 4 – 2,5 / 5 /10 – 12,5 / 25 /50 – 50 / 100 /200

Operating conditions

- Operating voltage (0...10V) : 14...30 V DC

- Operating voltage (4...20mA) : 12...30 V DC

- Operating temperature : 0...+50 °C

- Storage temperature : -20°C...+120°C

Connections

- Electrical connection : Schraubklemme im Gehäuse

- Process connection : Schlauchanschluss 3,5 mm oder 5,5 mm

Pressure measuring ranges

- 1/2/4mbar :

- 2,5/5/10mbar :

- 12,5/25/50mbar :

- 50/100/200mbar :

- other on request :

DSM2420

Sensor for simultaneous measuring flow velocity and filling level

The DSM2420 sensor is a combined sensor for simultaneous measuring flow velocity and level in open or accessible closed channels of all types and shapes.

Properties

- Dimensions : 180 x 48 x 36,5 mm ( L x B x H )

- Weight : ca. 1,5 kg

- Protection class : IP68

- Cable length (standard) : 15 m

- Bending radius : > 10 x D (Kabeldurchmesser 6,25mm) = > 62,5mm

- Temperature range : 0°C ... 50°C

- Mounting shoe material : V2A 1,5mm

Certificates

- EX / ATEX : IBExU 04 ATEX 1256

Measuring principle

- Flow velocity: Ultrasonic Doppler :

- Filling level: Differential pressure :

Flow velocity

- Measuring range : 0,01 - 4 m / s

- Measuring accuracy : +/- 5 % vom Momentanwert im Kanal

- Temperature drift : 0,1% / °C ( Meßspanne )

- Temperature drift : 0,05% / °C ( Nullpunkt )

- Output signal : 4 - 20 mA

Filling level

- Measuring ranges : 0 –1 m ; 0 – 2 m ; 0 – 4 m

- Measuring accuracy : < 0,2% v.E. Summe aus Nichtlinearität, Hysterese und Wiederholbarkeit

- Temperature drift : 0,005% / °C v.E. Meßspanne

- Temperature drift : 0,005% / °C v.E. Nullpunkt

- Material : Al2O3 (96%) aktive Fläche

- Output signal : 4 – 20 mA

- Zero point : norm 4 mA ( +/- 3 % )

ZDS-H

Precision pressure switch for high-pressure applications up to 2,000 bar

Can be used in oil, brake fluid, diesel, air and other gases.

With very good stability and overpressure resistance.

Properties

- Pressure range : 0...2.000 bar gestuft

- supply : 24 V DC

- Output : Relais 60 V AC/1A

- overload : 1,5 x Messbereich

- Med. connection : G 1/4 Zoll

- electrical connection : Schraubklemme

- feature : Tasten, LCD-Anz.

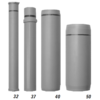

PPS-390

PPH float with magnet insert

for actuating monostable and bistable contacts

Variants

- 32 : AußenØ 26 x 180 mm, für RohraußenØ 32 u. 34 mm Gewicht ca. 38 g

- 37 : AußenØ 29,5 x 170 mm, für RohraußenØ 40 mm (PN 16) Gewicht ca. 62 g

- 40 : AußenØ 40 x 165 mm, für RohraußenØ 50 mm Gewicht ca. 145 g

- 50 : AußenØ 50 x 125 mm, für RohraußenØ 63 mm Gewicht ca. 156 g

VS-D250

Transmitter for ViscoScope viscosity sensors

Maximum flexibility for an optimal choice of measuring instrument: The VS-D250 transmitter is compatible with all ViscoScope® sensors of the types VA-100 and VA-300.

Properties

- Output card socket : 2

- External input : 0/4…20 mA | 0/2…10 V DC

- Power supply : 24V DC, 12 W

- Dimensions : 142 x 106 x 73 mm (L x B x H)

- Front : RS232, MODBUS RTU (Standard)

Display and Operation

- Lines : 4

- Pages : 2

- Character set : alphanumerisch

- Buttons : 3 (front)

Alarms

- system function :

- sensor diagnosis :

- Coil Temperature :

- 2 configurable LEDs :

optional outputs

- 0/4…20mA | 0/2…10V DC (active) :

- RS232 | RS485 :

- 2 SPDT-Relays: RS232 | RS485 :

Filter

- Moving average (200 measured values) :

TSR-CAN-03

CANopen transmitter for temperature measurement in media

High-quality stainless steel transmitter for precise temperature measurement in all stainless steel-compatible media

Measurement parameters

- Measuring range : -40…+80 °C (optional +150°C)

- deviation : ± 0,3 K (-40…+80 °C)

- Measuring element : Halbleiter

- measuring resolution : 10 Bit

- measuring grid : ab 5 ms

ElectricalConnection

- CAN protocol : CANopen 2.0 A, nach ciA DS 404

- Physical Layer : nach DIN 11898

- Operating voltage : 12…27 V ±20 %

Operating conditions

- Operating temperature : -40...+80 °C

- Storage temperature : -40°C...+120°C

- Shock resistance : 30g, Dauer: 14 ms bei Raumtemperatur

- Vibration resistance : 10g bei 20 bis 1000 Hz

NP-256

Level Switch - multiple 2...4 - pneumatic (hose)

very reliable and simple

sensors for scanning liquids, in

particular when used for overflow

protection. liquids can be

aggressive, sticky or highly contaminated

Properties

- Protection class EN60529 : IP 54

- connection thread : ab G2”

- Union nut : ab G2¾”

- Container connection flange : ab DN 25

- HoseØ : 13x2 mm

- Operating temperature : +60 °C

- medium temperatur : max. +60 °C

- Contact : Wechsler

- Switching capacity : 500 VA

- Switch-on point (Viton membrane) : 150 mm WS ±30 mm

- Switch-off point (MembraneViton) : 90 mm WS ±30 mm

Material

- Hose : PVC

- Screw fitting/grommet : PVC

- flange : PVC

- Connection head : PVC

Switching voltage

- silver : max. 250 V AC

- Gold : max. 24 V AC

Switching current

- silver : max. 6 A

- Gold : max. 100 mA

KST-20 Vento-RN

Climate control with aH-Controlled technology and Rn-Protected seal

The KST-20 Vento/RN is a climate control unit with aH-Controlled technology and Rn-Protected seal for ventilation and dehumidification of all types of private, commercial and industrial rooms. With the three operating modes for ventilation, dehumidification and radon measurement, the KST-20 Vento climate control unit can be used flexibly in almost all living, working and industrial areas.

Properties

- Power supply : 230 V AC

- Protection class : IP 65

- Dimensions (LxBxH) : 160 x 90 x 50 mm

- Housing : hochwertigem ASA+PC (UL 94 V-0) für harte Beanspruchung, flammwidrig und selbstverlöschend

- Signal output : I²C

Measuring range

- measuring range (Humidity) : 0…100 % rF

- Measuring accuracy (humidity) : ±2 %

- measuring range (Temperature) : -40…+80 °C

- Measuring accuracy (temperature) : ±0,2 °C

- measuring range (radon) : 0...1200 Bq/m³

- Adjustable limits : 80...1000 Bq/m³

Our application engineers advise you personally, comprehensively and professionally!

Simply contact us by phone or e-mail!