Cart

product added to request

MKL configure

T200.F-24V configure

ES-20 configure

QFS-5x | QFS-6x configure

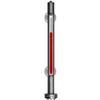

MKL

Magnetic Flap Indicator

The MKL level indicator is connected by its two connections to the container to be monitored (see connection example). According to the law of interconnected containers the level in the float chamber corresponds exactly to the level in the container

Properties

- connection : Flansch ab DN 15

- Material : rostfreier Edelstahl, PVC, PPH, PVDF

- Material flange : Edelstahl 1.4571, C22.8

- Material Float : Edelstahl, Titan, PVC, PPH, PVDF

- Number of contacts : beliebig

- Contact load : max 10 VA, max 230 V AC

- Display length : max. 6m

Operating temperature

- PTFE seal : max. 150 °C

- Stainless steel: Klingerit seal : max. 200 °C

- PVC : max. 60 °C

- PPH : max. 90 °C

- PVDF : max. 130 °C

Stainless steel float

- Weight : ~ 300 g

- Dimensions : Ø 52 x 270

- Operating pressure : 16 bar

- media density : ρ ≥ 0,70 g/cm³

Stainless steel float

- Weight : ~ 320 g

- Dimensions : Ø 52 x 270

- Operating pressure : 40 bar

- media density : ρ ≥ 0,75 g/cm³

Titanium float

- Weight : ~ 180 g

- Dimensions : Ø 52 x 150

- Operating pressure : 16 / 40 bar

- media density : ρ ≥ 0,73 g/cm³

PVC float

- Weight : ~ 331 g

- Dimensions : Ø 52 x 250

- Operating pressure : 6 bar

- media density : ρ ≥ 0,8 g/cm³

PPH float

- Weight : ~ 283 g

- Dimensions : Ø 52 x 250

- Operating pressure : 6 bar

- media density : ρ ≥ 0,69 g/cm³

PVDF float

- Weight : ~ 352 g

- Dimensions : Ø 52 x 250

- Operating pressure : 6 bar

- media density : ρ ≥ 0,85 g/cm³

T200.F-24V

Overfill protection with 24V direct connection

Level sensors type T-20_.F... are

approved by the DIBt (German

Institute for Structural Engineering) as liquid level limit switches for the overcharge protection of containers for storing water-dangerous liquids.

Connection

- Polyester junction box : PO/ET-520

- Polyethylene connection head : PE/ET-521

Properties

- Protection class EN60529 : IP 65

- connection thread : G 1", G 1¼", G 1½", G2", G3”

- Union nut : G 2¾", S 100x8

- Guide tube length : max. 6 m

- Operating temperature : max. 80 °C

- Operating pressure : atmosphärisch

- media density : ρ ≥ 0,6 g/cm³ (je nach Schwimmertyp)

- Switching hysteresis : typ. 2 mm

- Switching point tolerance : max. 2 mm

Power supply

- nominal voltage : 24 V DC (24…300V DC)

- Power consumption : ≤ 1 W

Output

- Output contact : 1 potentialfreier Wechselkontakt

- Switching voltage : max. 250 V AC / 30 V DC

- Switching current : max. 3 A AC / 3 A DC

- Switching capacity : max. 750 VA / 90 W

Optocoupler

- Switching voltage : max. 30 V

- Switching current : max. 100 mA

- displays : Betriebs-LED grün, Funktions-LED rot

- Switching delay : ca. 0,5 s Anzug/Abfall

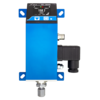

ES-20

Pressure limiter | Pressure monitor | Safety pressure limiter | Pressure regulator | electronic safety switching device

TÜV-certified, type-tested electronic safety switching device (SIL2)

Properties

- Operating voltage : 16...32 V DC (max. 5,9 W)

- Dimensions : 150 x 60 x 42 mm (L x B x H)

- Housing : Aluminium (eloxiert)

- Protection class : IP65

Approvals

- DGRL 2014/68/EU Kat:IV : Baumustergeprüft gemäß Druckgeräterichtlinie

- DIN EN12263:1998 : Kälteanlagen und Wärmepumpen Sicherheitsschalteinrichtungen zur Druckbegrenzung -Anforderungen und Prüfungen; Kategorie IV

- DIN EN378:2020 : Kälteanlagen und Wärmepumpen - Sicherheitstechnische und umweltrelevante Anforderungen

- DIN EN61508:2011 : SIL2

Operating conditions

- Pressure type : Relativdruck, Differenzdruck

- Temperature of the fluid : -40…+125 °C

- Ambient temperature : -20…+65 °C

- Parts in contact with media : Edelstahl

Connections

- Process connection Relative pressure (internal thread) : G ¼“

- Process connection differential pressure (internal thread) : G ⅛“

- Analogue current output : 1 x 4...20 mA

- Digital inputs/outputs (configurable) : 2 x Alarm / 1 x Alarm & 1 x Fernentriegelung

Measuring range relative pressure

- Nominal pressure (variable selectable) : -1...500 bar

- Overload pressure : 2 x Nenndruck

- Bursting pressure : 4 x Nenndruck

- Setting accuracy : 0,1 % vom Nenndruck

Measuring range differential pressure

- Nominal pressure : 0...1 mbar 0...10 mbar 0...50 mbar 0...100 mbar 0...250 mbar 0...1.000 mbar

- Overload pressure : 10 x Nenndruck

- Bursting pressure : 15 x Nenndruck

- Setting accuracy : 0,1 % vom Nenndruck

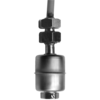

QFS-5x | QFS-6x

Teflon float switch for all kinds of liquids up to 150°C

The float of the QFS-50 and QFS-60 float switches is made of Teflon. Inside the float, one or two reed contacts with a movable permanent magnet are inserted as a switching element.

Technical Data

- Material : PTFE (Teflon)

- connection cable : Silikon, Teflon

- Operating temperature : max. +150°C

- Operating pressure : 1 bar

- media density : ρ ³ 0,75 g/cm³

- Switching system : Reed-Schalter

- Contact : Wechsler, NO, NC

- Inductive/capacitive loads : Unbedingt Kontaktschutz vorsehen

- Ex-protection optional : Elektrische Daten siehe EG-Prüfbescheinigung IBExU10ATEX 1089

Reed contact

- Switching current : 1 mA ... 1 A

- Switching voltage : 24 ... 250 V AC/DC

- Switching capacity : Max. 1A, 60 VA / 60 W

- Switching hysteresis : ca. 100 mm

- Switching angle : ca. +20°...–20°

Namur circuit (1kΩ/12kQ)

- Switching current / switching voltage : nur zum Anschluss an KR-163... oder andere „Namur”-Relais

- Switching hysteresis : ca. 100 mm

- Switching angle : ca. +20°...–20°

T205-0.F

Ex area zone 0 (category 1)

The magnetic immersion probes T20... are used to detect fill level limit values in containers for liquid media, where an explosive atmosphere of zone 0 (cat. 1) is present in the gas space above the liquid and Ex zone 1 (cat. 2) is present outside the container, in the area of the junction box.

Properties

- Protection class EN60529 cable : IP 68

- connection cable : max. 10 Meter PUR

- Sliding tube length : Max. 6000 mm

- Operating temperature : max. 120 °C

- F-Contact : 1 / 12 kΩ

Float

- Stainless steel ball 44 mm Ø : max. 15 bar | 0,60 g/cm³

- Stainless steel cylinder 27 mm Ø : max. 10 bar | 0,78 g/cm³

Our application engineers advise you personally, comprehensively and professionally!

Simply contact us by phone or e-mail!