Cart

product added to request

BK-390 configure

T-200.L configure

T-200.L 230V configure

TK-300 configure

XR-4x0 | XR-4x1 configure

W-35X configure

T205 PP

Magnetic immersion probes made of PP

Magnetic immersion probes for use with highly aggressive liquid media for detecting level limits in containers

Properties

- Protection class : IP 65

- Number of floats : 1x Typ 12 | 1x Typ 13

- connection cable : LiYY-Kabel 0,14 mm² | PVC-Litze 0,24 mm²

- Operating temperature : max. 60 °C

- Operating pressure : drucklos

- Number of contacts : 1x Schließer / Öffner

- Switching current : 1 A

- Switching voltage : 250 V AC

- Switching capacity : 50 W/VA

Float type

- Type 12 : Zylinder PP 19 mm Ø | Dichte 0,93 g/cm³

- Type 13 : Zylinder PP 25 mm Ø | 0,68 g/cm³

BK-390

Bistable change-over contact

Magnetically actuated changeover switch,

which permanently changes its electrical switching state as a result of a magnetic system passing by, depending on the direction of movement.

Properties

- Protection class EN60529 : IP 65

- Operating temperature : –25...+70 °C

- Wire cross-section max. : 1,5mm²

- Switching point distance between two contacts : min. 40 mm

- Switching hysteresis : ca. 10-15 mm

Material

- Housing : Polycarbonat

- Mounting clip : V2A, Kabelbinder (PP)

- Rivet : V2A

- Screw connection : M 20 x 1.5, Polyamid

Weight

- BK-390-50 : 137 g

- BK-390-63 / BK-380 : 140 g

Switching contact

- Switching voltage : 5...250 V AC/DC

- Switching current : 1mA...6 A AC/DC

- Switching capacity(min.) : 300 VA, 60 W

- Switching capacity(max.) : 5 mW

T-200.L

Leakage probes with general building authority approval

The leakage probes T-200.L are approved by the "DIBt" on the basis of the "WasBauPVO" for the detection of leaked liquids hazardous to water.

Connection

- Box : Polyesterdose (PO)

- Box : Polyethylen-Anschlusskopf (PE)

- Cable : Kabel (TPK)

- Plug : Stecker (ST)

Properties

- Protection class : IP 65

- Cable entry : PVDF-Verschraubung , PVC-Dichtung

- Material Float : PE

- Material leakage probe base : PE

- Cable : TPK (PVC Basis)

- Operating temperature : atmosphärisch

- Operating pressure : atmosphärisch

- media density : mit Schwimmer PE 52 ρ ≥ 1,05 g/cm³

- Switching hysteresis : typ. 2 mm

- Switching point tolerance : max. 2 mm

Resistance value

- Operational readiness : ca. 1 kΩ

- Leakage detection : ca. 12 kΩ

T-200.L 230V

Leakage probes with general building authority approval

The leakage probes T-200.L are approved by the "DIBt" on the basis of the "WasBauPVO" for the detection of leaked liquids hazardous to water.

Connection

- Box : Polyesterdose (PO)

Properties

- Protection class : IP 65

- Cable entry : PVDF-Verschraubung , PVC-Dichtung

- Material Float : PE

- Material leakage probe base : PE

- Cable : TPK (PVC Basis)

- Operating temperature : max. 60 °C

- Operating pressure : atmosphärisch

- media density : ρ ≥ 0,6 g/cm³

- Switching hysteresis : typ. 2 mm

- Switching point tolerance : max. 2 mm

Power supply

- nominal voltage : 24…230 V AC/DC

- Power consumption : ≤ 2 W

Output

- Output contact : 2 potentialfreie Wechselkontakte

- Switching voltage : max. 250 V AC / 30 V DC

- Switching current : max. 5 A AC / 5 A DC

- Switching capacity : max. 750 VA / 90 W

- displays : Betriebs-LED grün, Funktions-LED rot

- Switching delay : ca. 0,5 s Anzug/Abfall

- CE marking : siehe Konformitätserklärung

T204-0

Magnetic immersion probe made of stainless steel (1.4571) as a cable tail variant

For use with highly aggressive liquid media to detect level limit values in containers. Suitable for use in hazardous areas, zone 0 (category 1).

Properties

- connection : Polyesterdose | Aluminiumdose

- Protection class EN60529 : IP 65 Anschlussdose

- Connector plug : 3- und 6-fach

- connection thread : G 1/8" | G 3/8" | G 1/4" | G 1/2" | G 1" | G1 1/4" | G1 1/2" | G2" | G3"

- connection cable : LiYY max. 80 °C | PTFE-Litze, 0,24 mm² | Silikon max. 150 °C

- Sliding tube length : max. 1000 mm (Rohr Ø 8 mm) | 6000 mm

- Operating pressure : max. 20 bar

- Viscosity : < 100 cp

- Protection class EN60529 : IP 68 Führungsrohr

- Switching voltage : max. 250 V

- Switching hysteresis : ca. 2...5 mm

- Holding range : ca. 12 mm

- Contact function : monostabil | bistabil

Operating temperature

- ltdata. : max. +60...+150 °C

- ltdata. : min. –20... –10 °C

- ltdata. : höhere oder niedrigere Temperaturen auf Anfrage

Switching capacity

- Changeover contact : 60 W/VA

- normally open : 100 W/VA

- Normally closed contact : 60 W/VA

Switching current

- Changeover contact : max. 1 A

- NO/NC contact : max. 2 A

Contacts

- Changeover contact : 8

- normally open : 10

- Normally closed contact : 7

TK-300

Level transducer

T30... continuous magnetic immersible probes are used for quasi-acquisition of the filling level in containers with liquid media.

Properties TK-300

- connection : Polyesterdose | Aluminiumdose | Stecker nach DIN 43650

- Protection class socket / plug : IP 65

- Protection class EN60529 cable : IP 55

- Float type : 10 (14)

- connection cable : 1000 mm LiYY 0,5 mm² oder Silikon 0,5 mm²

- Sliding tube length : max. 6000 mm

- Operating pressure : max. 6 bar

- Resolution : 10 mm, 15 mm oder 1%, 2%, 5% je nach Auflösung

- CE marking : siehe Konformitätserklärung

Operating temperature

- PV : max. 60°C

- PE : max 80 °C

- PP : max. 90°C

MaterialDensity

- Type 10 : 0,72 g/cm³

- Type 14 : 0,72 g/cm³

- Type 18 : 0,82 g/cm³

XR-4x0 | XR-4x1

Electrode relay with ATEX

The electrode relays are used for conductive level detection.

levels. The possible applications extend

areas where conductive, liquid media are to be detected, controlled

to be detected, controlled or regulated. Hereby

level detection (overflow / dry run) as well as minimum / maximum

as well as minimum / maximum controls can be realised.

Protection class EN60529

- clamp : IP20

- Housing : IP40

Technical Data

- Operating temperature : -20...+60 °C

- Storage temperature : -30...+80 °C

- Output contacts : potentialfrei

- Switching voltage : min. 5 V | max. 250 V AC / 150 V DC

- Switching current : min. 5 mA | max. 5 A AC / 5 A DC

- Switching capacity : min. 300 mW | max. 100 VA / 50 W

- Quiescent current : umschaltbar

- Weight : ca. 250 g

- CE marking : siehe Konformitätserklärung

- Ex-protection/IECEx : siehe Prüfbescheinigung

Lub-VDT USB-Kit

Software and USB kit for configuration & evaluation

Properties

- details : folgen

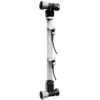

W-35X

Water Level Gauge with sight glass indicator

The water level gauge is particulary suitable for all liquid media which are aggressively hot and rapidly moved in a container, but are not too much contamined.

Properties

- Tank connection : Flansch ab DN 25 oder Verschraubung ab G ½"

- Material Float : PPH max. 2,5 bar, Glas max. 10 bar

- cable length : bei monostabilem Kontakt: Standard 2 m

- Number of contacts : beliebig

- Contact distance : min. 10 mm

- Temperature of the fluid : mit Plexiglasrohr max. +70 °C

- media density : ρ ≥ 0,95 g/cm³ | ρ ≥ 0,85 g/cm³ (auf Wunsch)

Properties W-350

- Material tube sight glass : transparentes PVC

- Temperature of the fluid : max. +60 °C

- Operating pressure : max. 2,5 bar

- Material flange : PVC

- Material connection with angle valve : PVC

- Material sealing ring : Gummi

Properties W-351

- Material tube sight glass : Hartglas, Plexiglas

- Temperature of the fluid : max. +120 °C

- Material flange : Rotguss

- Material connection with angle valve : Rotguss

- Material sealing ring : Silikon

- Operating pressure with glass tube : max. 10 bar

- Operating pressure with plexiglass tube : max. 2 bar

Properties W-352

- Material tube sight glass : Hartglas, Plexiglas

- Temperature of the fluid : max. +120 °C

- Material flange : Edelstahl

- Material connection with angle valve : Edelstahl 1.4571 als Bogen 90°

- Material sealing ring : PTFE und Viton

- Operating pressure with glass tube : max. 10 bar

- Operating pressure with plexiglass tube : max. 2 bar

Properties W-353

- Material tube sight glass : Hartglas, Plexiglas

- Temperature of the fluid : max. +120 °C

- Material flange : Edelstahl

- Material connection with angle valve : Edelstahl 1.4401

- Material sealing ring : PTFE und Viton

- Operating pressure with glass tube : max. 10 bar

- Operating pressure with plexiglass tube : max. 2 bar

Our application engineers advise you personally, comprehensively and professionally!

Simply contact us by phone or e-mail!