Cart

product added to request

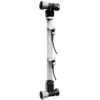

W-35X configure

W-35X

Water Level Gauge with sight glass indicator

The water level gauge is particulary suitable for all liquid media which are aggressively hot and rapidly moved in a container, but are not too much contamined.

Properties

- Tank connection : Flansch ab DN 25 oder Verschraubung ab G ½"

- Material Float : PPH max. 2,5 bar, Glas max. 10 bar

- cable length : bei monostabilem Kontakt: Standard 2 m

- Number of contacts : beliebig

- Contact distance : min. 10 mm

- Temperature of the fluid : mit Plexiglasrohr max. +70 °C

- media density : ρ ≥ 0,95 g/cm³ | ρ ≥ 0,85 g/cm³ (auf Wunsch)

Properties W-350

- Material tube sight glass : transparentes PVC

- Temperature of the fluid : max. +60 °C

- Operating pressure : max. 2,5 bar

- Material flange : PVC

- Material connection with angle valve : PVC

- Material sealing ring : Gummi

Properties W-351

- Material tube sight glass : Hartglas, Plexiglas

- Temperature of the fluid : max. +120 °C

- Material flange : Rotguss

- Material connection with angle valve : Rotguss

- Material sealing ring : Silikon

- Operating pressure with glass tube : max. 10 bar

- Operating pressure with plexiglass tube : max. 2 bar

Properties W-352

- Material tube sight glass : Hartglas, Plexiglas

- Temperature of the fluid : max. +120 °C

- Material flange : Edelstahl

- Material connection with angle valve : Edelstahl 1.4571 als Bogen 90°

- Material sealing ring : PTFE und Viton

- Operating pressure with glass tube : max. 10 bar

- Operating pressure with plexiglass tube : max. 2 bar

Properties W-353

- Material tube sight glass : Hartglas, Plexiglas

- Temperature of the fluid : max. +120 °C

- Material flange : Edelstahl

- Material connection with angle valve : Edelstahl 1.4401

- Material sealing ring : PTFE und Viton

- Operating pressure with glass tube : max. 10 bar

- Operating pressure with plexiglass tube : max. 2 bar

Our application engineers advise you personally, comprehensively and professionally!

Simply contact us by phone or e-mail!