Cart

XR-4x2 configure

ES-20 configure

TK-308 configure

CS-11

CO2 Sensor with digital Interface

Digital CO2 sensor CS-11 for measuring carbon dioxide concentration in mobile applications.

Properties CS-11

- Measured variable: : CO2

- Measuring range: : 0…5.000 ppm

- Measuring principle: : optisch, NDIR

- Housing : Kunststoff

- measuring grid : 2 sec.

- Accuracy : ± 50 ppm

- Protocol : I²C-Bus

- Operating conditions Temperature : -0°C … 50°C

- Operating conditions Humidity : 0…85 % rH

- Storage conditions Temperature : -30°C … 70 °C

- Storage conditions Humidity : 0…85 % rH

Properties MV-CAN

- Housing : Plastik

- Mounting : Hutschienenmodul für Einbau in Schaltschrank

- Operating voltage : 10…48 V

- measuring grid : 2 sec.

- CAN protocol : CANopen 2.0 A nach CiA DS 404

- Physical Layer : nach ISO 11898

- Option : Bereitstellung des EDS-Files

- Operating temperature : -40°C … +80°C

- Storage temperature : -40°C … +120 °C

T204.F

Immersible Magnetic Probes Ex area zone 0 (Cat 1)

Properties

- connection : Polyester Dose | Aluminium Dose

- Protection class : IP 65 Dose

- number of floats : max. 4x

- Operating temperature : max. 135 °C

- F-Contact : 1 / 12 kΩ

- Number of additional contacts : max. 3x Wechsler | 5x Schließer | 3x Öffner

- Switching current : 1 A, 2 A (nur mit Schirmung)

- Switching voltage : 230 V AC

Float

- Stainless steel ball 52mm Ø : max. 20 bar | 0,75 g/cm³

- Stainless steel ball 61 mm Ø : max. 20 bar | 0,65 g/cm³

- Stainless steel cylinder 44 mm Ø : max. 15 bar | 0,76 g/cm³

- min. contact gap type 03 : 75 mm

- min. contact gap type 04 : 85 mm

- min. contact gap type 09 : 75 mm

Switching contacts and switching capacity

- Changeover contact : max. 3x | 60W/VA

- normally open : max. 5x | 100 W / VA

- Normally closed contact : max. 3x | 60 W/VA

XR-4x2

Electrode relay with ATEX and WHG approval

The electrode relays are used for conductive level detection.

levels. The possible applications extend

areas where conductive, liquid media are to be detected, controlled

to be detected, controlled or regulated. Hereby

level detection (overflow / dry run) as well as minimum / maximum

as well as minimum / maximum controls can be realised.

Protection class EN60529

- clamp : IP20

- Housing : IP40

Technical Data

- Operating temperature : -20...+60 °C

- Storage temperature : -30...+80 °C

- Output contacts : potentialfrei

- Switching voltage : min. 5 V, max. 250 V AC / 150 V DC

- Switching current : min. 5 mA, max. 5 A AC / 5 A DC

- Switching capacity : min. 300 mW, max.100 VA / max. 50 W

- CE marking : siehe Konformitätserklärung

- Ex-protection/IECEx : siehe Baumusterprüfbescheinigung

- Weight : ca. 170 g

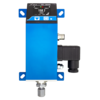

ES-20

Pressure limiter | Pressure monitor | Safety pressure limiter | Pressure regulator | electronic safety switching device

TÜV-certified, type-tested electronic safety switching device (SIL2)

Properties

- Operating voltage : 16...32 V DC (max. 5,9 W)

- Dimensions : 150 x 60 x 42 mm (L x B x H)

- Housing : Aluminium (eloxiert)

- Protection class : IP65

Approvals

- DGRL 2014/68/EU Kat:IV : Baumustergeprüft gemäß Druckgeräterichtlinie

- DIN EN12263:1998 : Kälteanlagen und Wärmepumpen Sicherheitsschalteinrichtungen zur Druckbegrenzung -Anforderungen und Prüfungen; Kategorie IV

- DIN EN378:2020 : Kälteanlagen und Wärmepumpen - Sicherheitstechnische und umweltrelevante Anforderungen

- DIN EN61508:2011 : SIL2

Operating conditions

- Pressure type : Relativdruck, Differenzdruck

- Temperature of the fluid : -40…+125 °C

- Ambient temperature : -20…+65 °C

- Parts in contact with media : Edelstahl

Connections

- Process connection Relative pressure (internal thread) : G ¼“

- Process connection differential pressure (internal thread) : G ⅛“

- Analogue current output : 1 x 4...20 mA

- Digital inputs/outputs (configurable) : 2 x Alarm / 1 x Alarm & 1 x Fernentriegelung

Measuring range relative pressure

- Nominal pressure (variable selectable) : -1...500 bar

- Overload pressure : 2 x Nenndruck

- Bursting pressure : 4 x Nenndruck

- Setting accuracy : 0,1 % vom Nenndruck

Measuring range differential pressure

- Nominal pressure : 0...1 mbar 0...10 mbar 0...50 mbar 0...100 mbar 0...250 mbar 0...1.000 mbar

- Overload pressure : 10 x Nenndruck

- Bursting pressure : 15 x Nenndruck

- Setting accuracy : 0,1 % vom Nenndruck

T205 VA

Stainless steel magnetic immersion probes

Magnetic immersion probes for use with highly aggressive liquid media for detecting level limits in containers

Properties

- Protection class : IP 65

- Number of floats : max. 2x Typ 08

- connection cable : Silikon Litze

- Operating temperature : max. 100 °C

- Operating pressure : max. 10 bar (Zylinder)

- Number of contacts : max. 2 x Schließer/ Öffner wahlweise durch 180°-Drehung des Schwimmers bei 2 Schwimmern

- Switching current : 1 A

- Switching voltage : 250 V AC

- Switching capacity : 50 W/VA

- Sliding tube length : max. 1000 mm

- media density : Typ 08: 0,78 g/cm³

- float : Zylinder Edelstahl 1.4571 27 mm Ø

- min. contact distance with several floats : 50 mm

TK-308

Liquid Level Measuring Instruments Series

T30... continuous magnetic immersible probes are used for quasi-acquisition of the filling level in containers with liquid media.

Technical Data

- Protection class socket / plug : IP 65

- Protection class EN60529 cable : IP 55

- Float type : 11,12, 15, 17

- connection cable : 1000 mm LiYY 0,5 mm² oder Silikon 0,5 mm²

- Sliding tube length : max. 6000 mm

- Operating pressure : max. 6 bar

- Resolution : 7,5 mm | 10 mm | 15 mm | 20 mm | 1 % | 2 % | 5 %

- Accessories : R/I-Wandler TK-101

Operating temperature

- PVC : max. 60 °C

- PE : max. 80 °C

- PP : max. 90 °C

MaterialDensity

- Type 11 : 0,60 g/cm³

- Type 12 : 1,00 g/cm³

- Type 15 : 0,59 g/cm³

- Type 17 : 0,63 g/cm³

FluidIX Lub-6

Inline-capable oil condition sensor based on a multi-channel infrared measuring cell for permanent monitoring of the oil condition and prevention of machine damage

Based on non-dispersive infrared technology (NDIR), ZILA GmbH has developed an inline-capable measuring system that permanently monitors the oil condition directly in the system. The optical measuring system consists of a multi-channel infrared measuring cell with associated electronics and peripherals.

General information

- Housing : Robustes Aluminiumgehäuse

- Operating voltage : 18...36V DC (max. 400 mA @18V)

- Dimensions : 150 x 119 x 82 mm (L x B x H)

Operating conditions

- Operating temperature: : 0...+70 °C (optional 0...+90 °C)

- Maximum operating pressure: : 10 bar (optional 30 bar)

- Storage temperature: : -40...+90 °C

Connection

- ModBus TCP/IP : Ethernet-Port für Kommunikation über herstellerunabhängiges Busprotokoll

- Digital I/O ports : 1x Digital In 18...36V (10 mA max.), 4x Digital Out 18...36V (5 mA max.)

Operation

- User Interface : grafisch über Weboberfläche im eingebundenen Netzwerk

Our application engineers advise you personally, comprehensively and professionally!

Simply contact us by phone or e-mail!