Cart

product added to request

product added to request

NP-25X configure

TSR-CAN-03 configure

MTA configure

EF2 24...230 V configure

TK-32X configure

ES-21 configure

NP-25X

Pneumatic level switch

Reliable & simple probe for sensing aggressive, sticky or heavily contaminated liquids, especially suitable as overflow protection.

Properties NP-250 | NP-252

- Connection head : PA

- Protection class EN60529 Connection head : IP 54

- connection thread : ab G½”

- Container connection flange : ab DN 25

- Pitot tube material : PVC

- Material Screw connection : PVC

- Material flange : PVC

- Hose Ø : 16 mm / 25 mm

- Operating temperature : max. +60 °C

- medium temperatur : max. +60 °C

- Contact : Wechsler

- Switching voltage silver : 250 V AC

- Switching voltage gold : 24 V AC

- Switching current silver : 6 A

- Switching current gold : 100 mA

Properties NP-251 | NP-253

- Connection head : PS

- Protection class EN60529 Connection head : IP 54

- connection thread : ab G½”

- Container connection flange : ab DN 25

- Pitot tube material : 1.4571

- Material Screw connection : 1.4571

- Material flange : 1.4571

- Hose Ø : 15 mm / 28 mm

- Operating temperature : max. +60 °C

- medium temperatur : max. +90 °C

- Contact : Wechsler

- Switching voltage silver : 250 VAC

- Switching voltage gold : 24 V AC

- Switching current silver : 6 A

- Switching current gold : 100 mA

TSR-CAN-03

CANopen transmitter for temperature measurement in media

High-quality stainless steel transmitter for precise temperature measurement in all stainless steel-compatible media

Measurement parameters

- Measuring range : -40…+80 °C (optional +150°C)

- deviation : ± 0,3 K (-40…+80 °C)

- Measuring element : Halbleiter

- measuring resolution : 10 Bit

- measuring grid : ab 5 ms

ElectricalConnection

- CAN protocol : CANopen 2.0 A, nach ciA DS 404

- Physical Layer : nach DIN 11898

- Operating voltage : 12…27 V ±20 %

Operating conditions

- Operating temperature : -40...+80 °C

- Storage temperature : -40°C...+120°C

- Shock resistance : 30g, Dauer: 14 ms bei Raumtemperatur

- Vibration resistance : 10g bei 20 bis 1000 Hz

MTA

Mechanical tank level indicator

The tank level indicator is a mechanically actuated indication operating "on the spot”. It permits a high degree of safety and flexibility thanks to separate points of measurement and indication.

Properties

- Tank connection : Flansch ab DN 80 (Sonderanschlüsse auf Wunsch)

- Material : siehe Maßbild

- Material Tube : PVC, transparent | Ø 50 x 1,8 | Ø 63 x 3,0

- Operating temperature : –20...+60 °C

- Operating pressure : atmosphärisch

Material Float

- PPH : Ø 70 mm 460 g

- PVC : Ø 70 mm 455 g

- PPH : Ø 40 mm 370g

- PE : Ø 70 mm ca. 450 g

Material Rope

- PPH : (rot, Ø 2 mm) ~ 2 g/m

- Polyester : (bunt, Ø 2 mm) ~ 4 g/m

- PTFE : (weiss, Ø 3 mm) ~ 10 g/m

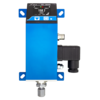

EF2 24...230 V

Conductive electrodes with 24...230 V direct connection

The EF2 overfill protection (24...230 V AC/DC) is approved by "DIBt" as an overfill protection for liquids hazardous to water.

Properties

- connection : Polyesterdose (PO)

- Protection class : IP 65

- connection thread : G1"

- Union nut : auf Wunsch

Material

- Screw connection : PE, PVC, PPH, PTFE

- Sensor rods : Edelstahl (1.4571), Hastelloy C, Titan, Tantal

- Operating pressure : atmosphärisch

- Resistance value of line monitoring : 100 kΩ

- Sensitivity range : einstellbar 2…100 kΩ

Operating temperature

- PE : atmosphärisch

- PVC : atmosphärisch

- PPH : 90 °C

- PTFE : 100 °C

Power supply

- nominal voltage : 24…230 V AC/DC

- Power consumption : < 2 W

Output

- Output contact : 2 potentialfreie Wechselkontakte

- Switching voltage : max. 250 V AC /30 V DC

- Switching current : max. 5 A AC / 5 A DC

- Switching capacity : max. 750 VA / 90 W

- displays : Betriebs-LED Grün, Funktions-LED Rot

- Switching delay : ca. 0,5 s Anzug / Abfall

- CE marking : siehe Konformitätserklärung

TK-32X

Luminous Row Displays

Luminous row displays of type series TK-320...TK-322 are used for visually displaying process states such as filling levels.

Type

- TK-320 : Schaltschrankeinbaugehäuse 24 x 96 mm

- TK-321 : Schaltschrankeinbaugehäuse 24 x 96 mm

- TK-322 : 19” Karteneinschub 7 TE, 3 HE

Properties

- Protection class EN60529 : IP 52

- Operating temperature : – 20 °C...+60 °C

- nominal voltage : 24 V DC...230 V AC

- Input : 0(4)...20 mA | 0(2)...10 V DC | 5...10kΩ

- Output : 4...20 mA | Bürde max. 500 Ω

- Relay : 2 x Umschalter max. 230 V | min. 5 V | max. 3 A | min 1 mA

Display

- Number of LEDs : 33 (rot/grün); 32 (TK-322)

- Resolution : ca. 3,5 %

- Error : ± 1 LED

- connection : Schraubklemmen

- connection TK-322 : Steckerleiste

- Input : 0(4)...20 mA | 0(2)...10 V DC | 5...10kΩ

- Output : 4...20 mA | max. load 500 Ω

- Relay(2xSwitch) : max. 230 V | min. 5 V

- Relay(2xSwitch) : max. 3 A | min. 1 mA

T205-0

Immersible Magnetic Probe made of PVC, PE, PPH, PTFE or stainless steel (1.4571)

Magnetic immersion probes for use with highly aggressive liquid media for detecting level limits in containers

Properties

- Protection class : IP 68 Kabel

- Float type : max. 4x Zylinder Edelstahl 27 mm Ø

- connection cable : 1000 mm PUR Blau

- Sliding tube length : max. 6000 mm

- Operating temperature : max. 120 °C

- Operating pressure : max. 10 bar (Schwimmer)

- media density : 0,78 g/cm³

- Number of contacts : max. 2 Schließer / 2 Öffner

- Switching current : 1A, 2A

- Switching capacity : 50 W/VA

- min. contact distance with several floats : 50 mm

ES-21

Electronic safety switching device with 1 safety function

TÜV-certified, type-tested electronic safety switching device (SIL2)

Properties

- Operating voltage : 16...32 V DC (max. 5,9 W)

- Dimensions : 150 x 60 x 42 mm (L x B x H)

- Housing : Aluminium (eloxiert)

- Protection class : IP65

Approvals

- DGRL 2014/68/EU Kat:IV : Baumustergeprüft gemäß Druckgeräterichtlinie

- DIN EN12263:1998 : Kälteanlagen und Wärmepumpen Sicherheitsschalteinrichtungen zur Druckbegrenzung -Anforderungen und Prüfungen; Kategorie IV

- DIN EN378:2020 : Kälteanlagen und Wärmepumpen - Sicherheitstechnische und umweltrelevante Anforderungen

- DIN EN61508:2011 : SIL2

Measuring ranges

- Measuring range relative pressure (nominal pressure) : -1…500 bar

- Measuring range differential pressure (nominal pressure) : 0…1 mbar - 0…1.000 mbar

- Setting accuracy (from nominal pressure) : 0,1 %

Operating conditions

- Pressure type : Relativdruck, Differenzdruck

- Temperature of the fluid : -40…+125 °C

- Ambient temperature : -20…+65 °C

- Parts in contact with media : Edelstahl

process connection

- Version relative pressure : G ¼“ Innengewinde

- Version differential pressure : G ⅛“ Innengewinde

- Adapter for process connection : 6mm; 8mm oder 10mm

electrical connection

- Analogue current output : 1x 4…20 mA

- Digital inputs/outputs : 2x Alarm oder 1x Alarm & 1x Fernentriegelung

Load capacity of the switching contacts DC (24V)

- DC1 : 16 A

- DC13 : 1,5A

Load capacity of the switching contacts AC (230V)

- AC1 : 16 A

- AC3 : 10 A

- AC15 : 7 A

ZDS-H

Precision pressure switch for high-pressure applications up to 2,000 bar

Can be used in oil, brake fluid, diesel, air and other gases.

With very good stability and overpressure resistance.

Properties

- Pressure range : 0...2.000 bar gestuft

- supply : 24 V DC

- Output : Relais 60 V AC/1A

- overload : 1,5 x Messbereich

- Med. connection : G 1/4 Zoll

- electrical connection : Schraubklemme

- feature : Tasten, LCD-Anz.

Aero_aH100

Exhaust air fan with integrated dehumidification control for automatic room dehumidification

Dehumidification control, including integrated indoor and outdoor climate sensor. Controlled dehumidification takes place by comparing the indoor and outdoor climate. To support room dehumidification, a ventilation fan can be directly connected and controlled via the Aero_aH 100.

Properties

- Power supply : 230V~ 50Hz

- power consumption : 8 W

- Protection class : IPX4

- flow rate : 78 m³/h bis zu 92 m³/h

- color : verkehrsweiß, ähnlich RAL 9016

- Material : Kunststoff

- Noise level : 27 dB(A) / 32 dB(A)

- Signal output : I²C

Measuring range

- measuring range (Humidity) : 0…100% rF

- Measuring accuracy (humidity) : ± 2%

- measuring range (Temperature) : -40...+80°C

- Measuring accuracy (temperature) : ± 0,2°C

Our application engineers advise you personally, comprehensively and professionally!

Simply contact us by phone or e-mail!