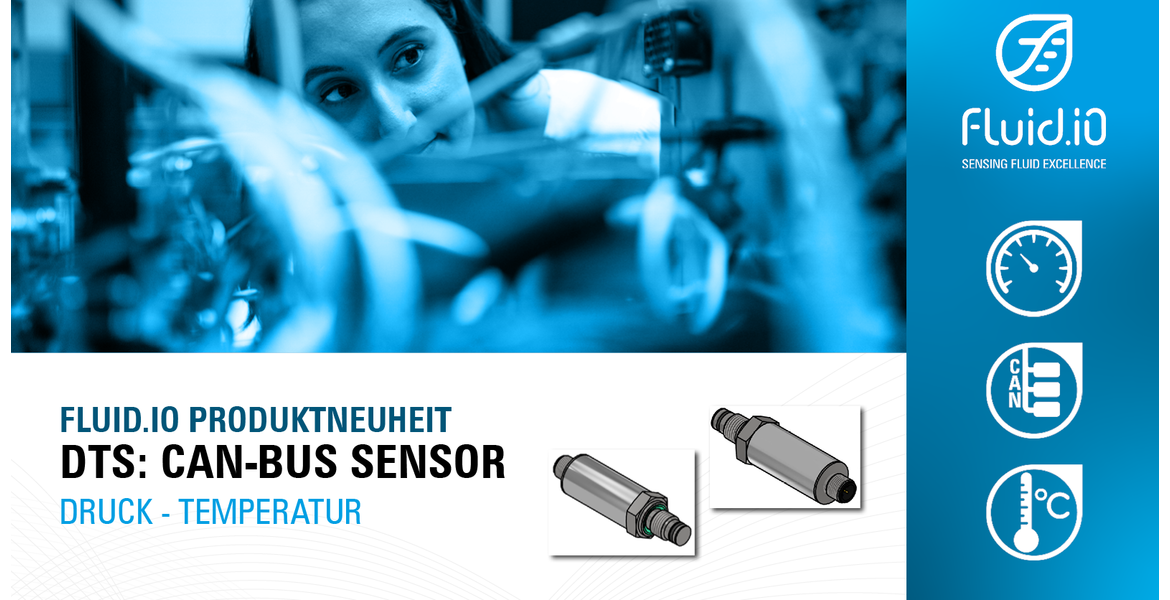

Nouveau capteur combiné de pression et de température avec interface de bus CAN pour la technologie de mesure de processus

-

Fluid.iO Sensor + Control GmbH & Co. KG

Fluid.iO Sensor + Control GmbH & Co. KG

- 9 sept. 2025

- 10

- 1.8 minutes

With the DTS-CAN from Fluid.iO, you can measure the process pressure and the process temperature at one measuring point in one sensor.

Pressure and temperature are among the most frequently measured process variables in process measurement technology. Simultaneous monitoring of process temperature and process pressure at a single measuring point therefore offers many advantages and opens up a wide range of applications.

The DTS-CAN is equipped with a CAN bus interface, a reliable and future-proof communication solution for modern automation and control environments. The standardized interface allows it to be easily integrated into existing systems, ensuring smooth data transmission.

The sensor combines precise measurement accuracy with a robust design, making it ideal for demanding industrial applications.

DTS-CAN Product Highlights:

- Robust stainless steel housing

- Suitable for all media and applications suitable for stainless steel

- Wide, adjustable pressure measuring range

DTS-CAN Technical Specifications:

| Feature | techn. data |

| Pressure measuring range | (-1) 0…100 bar |

| Temperature measuring range | -20…+100 °C |

| Process connection | G 1/4“ |

| Electrical connection | M12 Connection |

| Operating voltage | 9...27V |

| Dimensions | 75x22 mm |

DTS-CAN Advantages:

-

Reliable data communication via CAN bus

-

Easy system integration thanks to a standardized interface

-

Robust design for industrial environments

-

High precision in process measurement technology

Typical Applications:

-

Monitoring of pressure and medium temperature in hydraulic systems

-

Protection against overload or overheating

-

Process control in reactors and vessels

-

Ensuring constant pressure and temperature conditions during reactions

-

Monitoring of pressure and temperature in pipelines, tanks, and pasteurization systems

-

Control of steam pressure and temperature in turbine and boiler systems

-

Monitoring of pumps, lines, and storage tanks

-

Efficient control of filtration and treatment processes

-

Process monitoring in pipelines and conveyor systems

-

Condition monitoring (predictive maintenance)

-

Protection and monitoring of pumps, compressors, and motors

EK-CAN: PC software for convenient configuration and sensor testing

All Fluid.iO CAN sensors are configured with the desired preset node ID and baud rate during production and testing upon customer request.

Customers can later edit these settings using our EK-CAN software. Additionally, EDS files can be generated, measurement data can be recorded, and sensor tests can be performed.

EK-CAN

Programme PC pour capteurs CANopen

Logiciel d'évaluation et de configuration pour les capteurs CANopen Fluid.iO

DTS-CAN

Flexible, digital pressure and temperature sensor with CAN bus

Media-immersed, flush-mounted, stainless steel pressure-temperature sensor with CAN bus

Nos ingénieurs d'application vous conseillent de manière personnelle, complète et professionnelle !

Il suffit de nous contacter par téléphone ou par courrier électronique !